Product Design and Development Services

Realizing Your Vision through Precision Manufacturing Through Our State-of-the-Art Facility

USA's Trusted Expert in Contract Manufacturing for Two Decades

Welcome to a world of endless possibilities with MFG One, the leading contract manufacturing organization providing comprehensive product design and development solutions across the globe. With a focus on excellence and innovation, we specialize in crafting bespoke products tailored to meet the needs of both commercial enterprises and discerning consumers.

From the inception of an idea to its successful commercialization, we guide you through every step of the product development journey with precision and expertise.

Advanced

Manufacturing Capabilities

Throughout our years in the industry, we’ve continually expanded our manufacturing capabilities. Explore our range of product design and development services, and discover how we can bring your concepts to life with precision and efficiency.

Research and Prototyping

Design &

Rendering

3D Printing Design & Modeling

Printed Circuit Board Assembly

Plastic Injection Molding

Electro-Mechanical

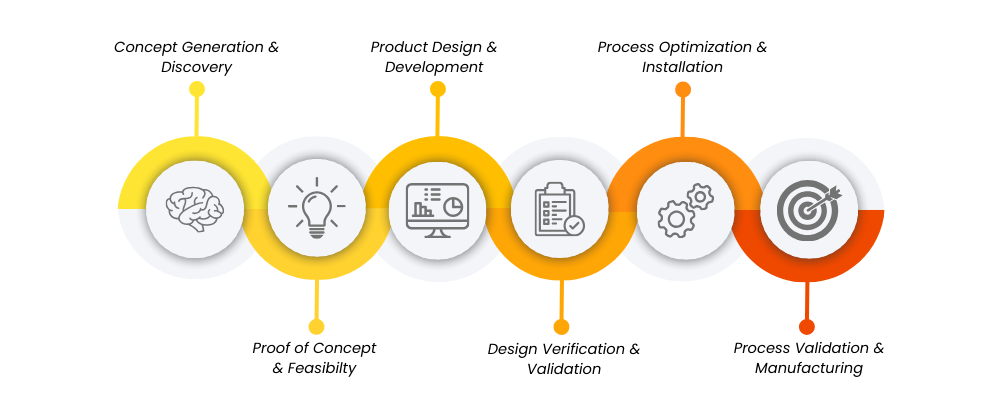

5 PHASEs OF

PRODUCT DEVELOPMENT

From the inception of an idea to its successful commercialization, we guide you through every step of the product development journey with precision and expertise.

phase # 1

Product Device

Concept Development

We collaborate closely with you to refine your concept, conducting thorough research to explore feasibility, understand user needs, and assess market fit. This involves a deep dive into market trends, user preferences, and technological possibilities to ensure your product concept is positioned for success.

phase # 2

Development

Our expert engineers and designers meticulously transform your concept into detailed blueprints, ensuring every detail is refined for optimal functionality, quality, and manufacturability.

phase # 3

Validation, Verification & Regulatory Clearances

We conduct rigorous verification and validation tests to ensure the product meets industry standards and exceeds customer expectations, particularly for products that rely on quality such as medical equipment. Our focus on quality-driven products ensures compliance with regulatory requirements.

phase # 4

Manufacture

We ensure a seamless transition from design to production, delivering high-quality products efficiently and cost-effectively. From assembly to optimizing your production processes, we are with you every step of the way.

phase # 5

Aftermarket Services

We provide comprehensive aftermarket services to support our clients throughout the product lifecycle. Our services include maintenance, repairs, and upgrades, as well as continuous assembly and 3PL fulfillment, both domestically and internationally.

Streamlining Product Design and Development

Exploring Optimization through VAVE Services and DFM, DFX, and DFT Principles. At MFG One, we understand the importance of efficiency and optimization in product design and development. By streamlining the entire process, we empower our clients to bring their ideas to market faster and more cost-effectively. As your product and medical contract manufacturer, we offer the following optimization services:

VAVE Services

DFMA (Design for

Manufacturing Assembly)

DFX

(Design for Excellence)

DFT

(Design for Test)

New Product Introduction

PHASES OF

PRODUCT DEVELOPMENT

Partner with MFG One for Product Design and Development Services

Whether you are looking for product design services, 3PL fulfillment services, or a contract medical device manufacturer, we've got you covered. We service commercial businesses nationally and internationally including the US, Canada, United Kingdom, Mexico, and beyond.

Ready to bring your product to life? Contact MFG One today for more information about our product design and development solutions.