Product design services have always been vital to a product’s success. A compelling aesthetic, combined with thoughtful functionality, can be the difference between a product that stands out and one that blends into the crowd. Great product design is about more than looks; it’s about creating a product that people love to use, all while keeping manufacturing costs in mind to ensure a successful and profitable product.

At MFG One, we understand the significance of a well-designed product. That’s why we offer comprehensive product design and engineering services to guide you through every step of the process, from concept to market-ready product. This blog explores the key stages of our product design process and how it will benefit your business.

Phase 1: Conceptual Design

The first phase involves conceptual design, where ideas are born. This phase sets the tone for the entire product development process and focuses on generating and refining innovative solutions tailored to specific market needs. Here’s how we approach this initial phase:

Ideation and Brainstorming:

The product design and development process begins with ideation and brainstorming. This creative phase involves generating ideas and potential solutions to address the identified market need or problem.

- Our design team uses techniques such as mind mapping, sketching, and collaborative workshops to stimulate creativity and encourage out-of-the-box thinking.

Concept Refinement:

As part of our product design services, we will refine the ideas, considering factors like functionality, aesthetics, usability, and manufacturability.

- Our team evaluates the feasibility of each concept, ensuring that the final design aligns with the client’s objectives and budget.

3D Visualization:

Using cutting-edge software, we create 3D models to visualize the product, enabling clients to see their concept take shape.

- This stage of electronic product design and development allows for the early detection of design flaws and facilitates iterative improvements before moving to the physical prototyping phase. This approach saves time and resources while ensuring the final product aligns perfectly with the client’s vision.

This initial phase is fundamental in setting a solid foundation for the following detailed design work, ensuring the final product is both innovative and feasible.

Phase 2: Design Development

In the second phase of our product design services, we focus on transforming the initial concept into a tangible design. This includes:

Form and Function:

Our designers balance aesthetics with functionality, ensuring the product is visually appealing and usable. We consider the following to create a product that is intuitive and enjoyable to use:

- Ergonomics,

- User experience

- Interface design

Material Exploration:

Our product design services team will explore various materials, considering factors like:

- Durability

- Cost

- Sustainability

- Regulatory compliance

Our team evaluates the pros and cons of each material, ensuring the selected option aligns with the product’s requirements and brand identity.

Color and Finish:

The perfect color palette and finish are selected to align with the product’s identity and brand. We consider the following factors to create a cohesive visual language:

- Brand identity

- Target audience preferences

- Emotional connections/triggers

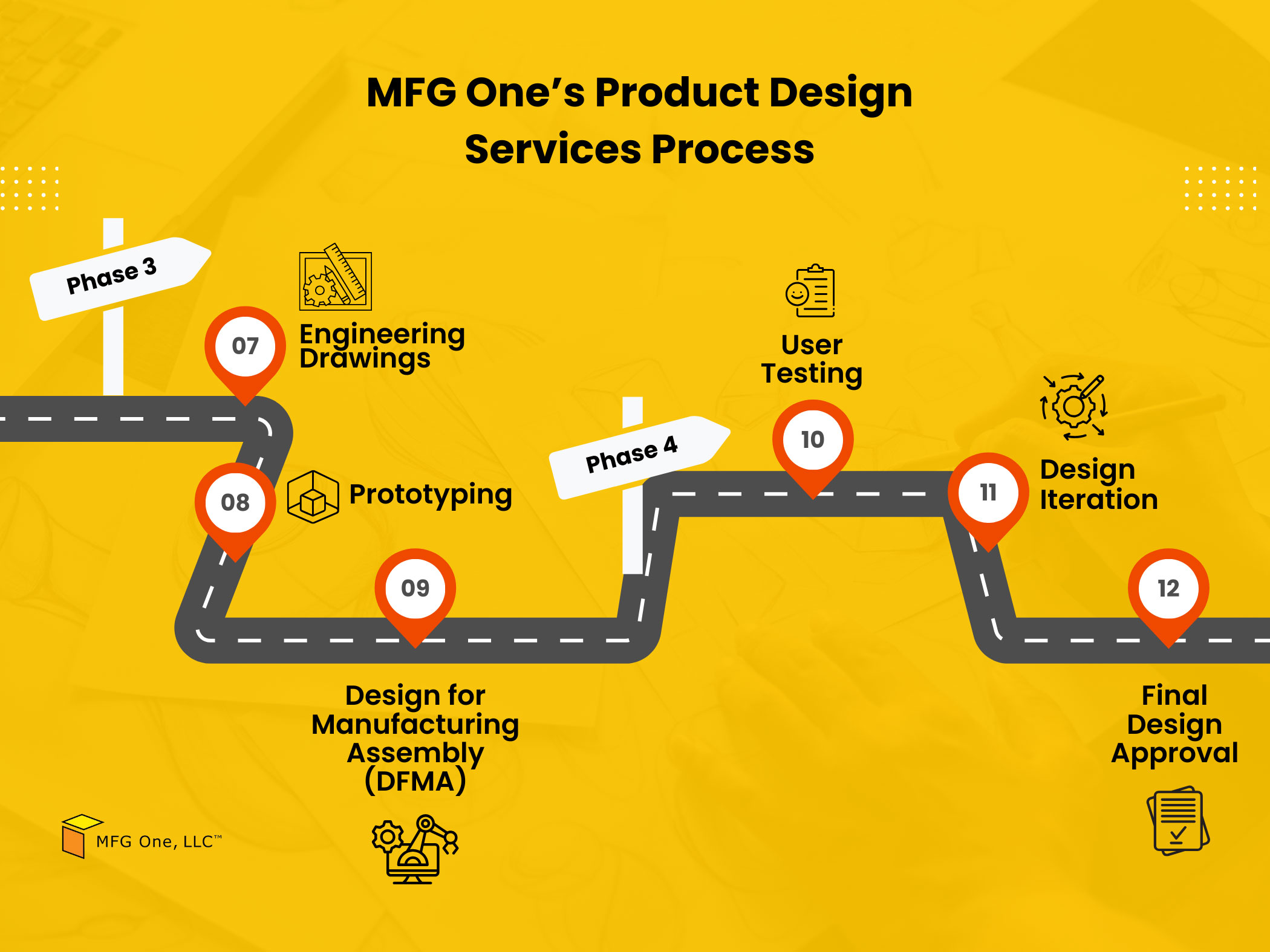

Phase 3: Technical Design

The next step in our product design services focuses on engineering for manufacturability. We refine the design with precision, ensuring it’s ready for efficient production and a seamless market entry.

This phase involves:

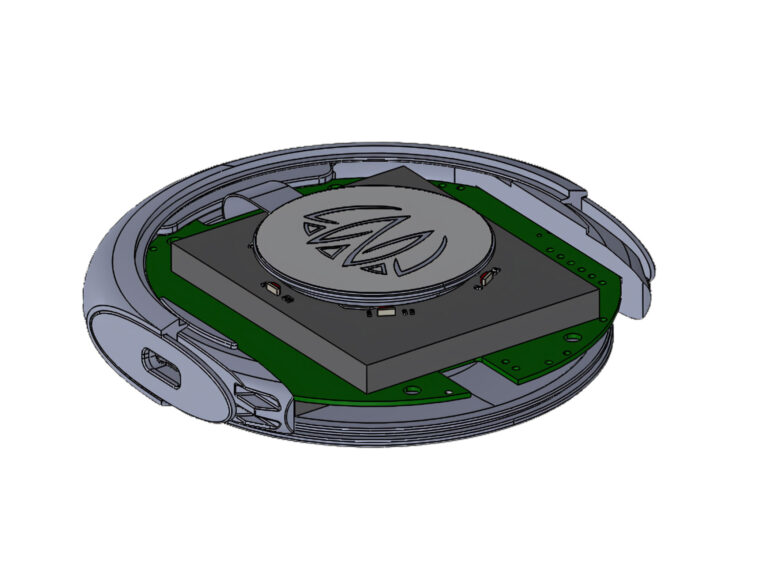

Engineering Drawings:

Once the overall design is established, detailed engineering drawings are created. These technical documents provide precise specifications for each component, including dimensions, tolerances, and assembly instructions. They are an important part of the manufacturing process.

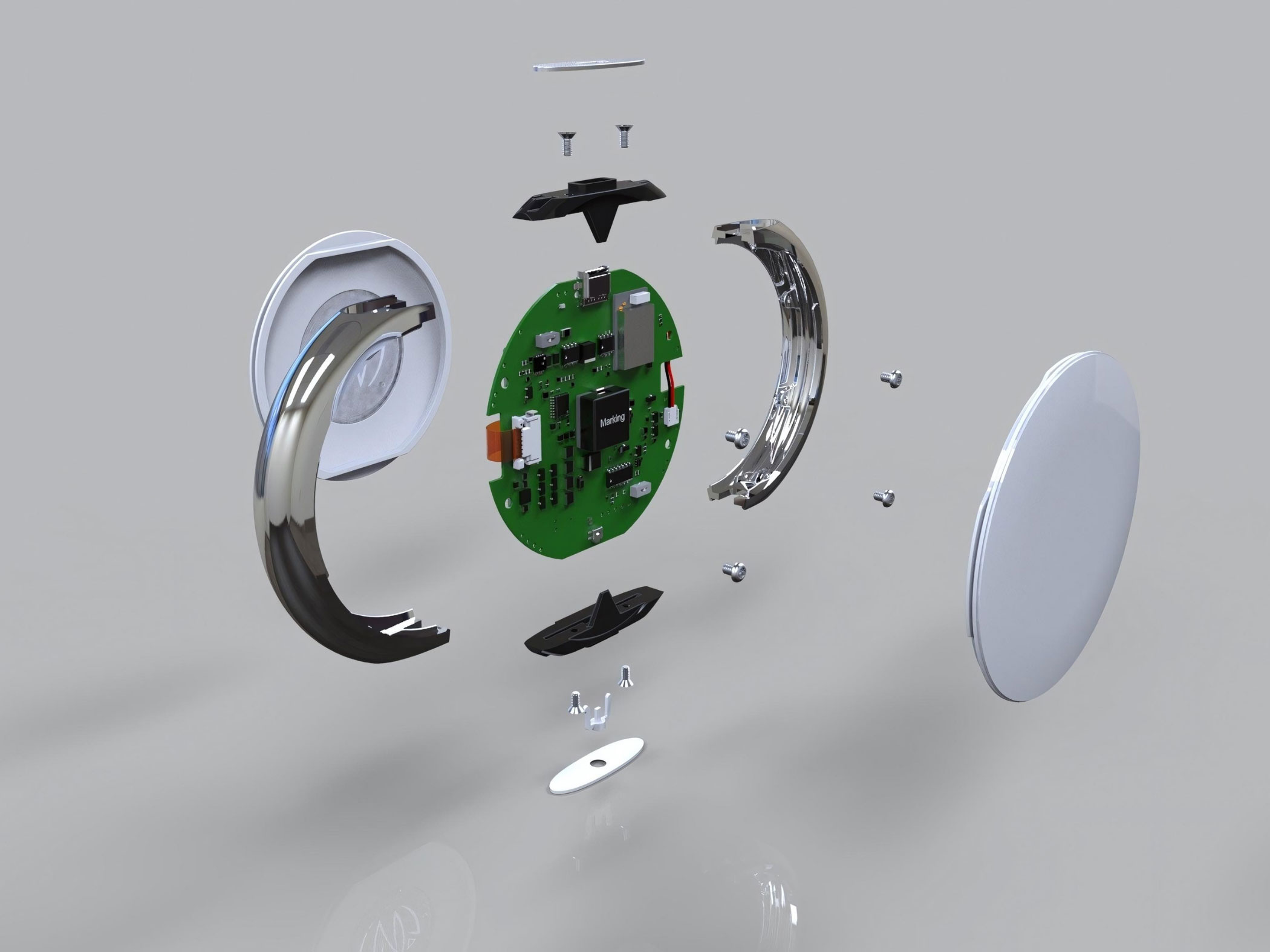

Prototyping:

Prototyping is a critical part of our contract manufacturing services. It involves creating physical product models to test its functionality, ergonomics, and overall design. This allows us to validate design assumptions, identify potential issues, and make necessary adjustments before moving to production.

Design for Manufacturing Assembly (DFMA):

In the DFMA stage, we meticulously analyze every design aspect to ensure it’s optimized for streamlined and cost-effective production. This involves a careful evaluation of:

- Material choices

- Assembly techniques

- Manufacturing processes

By identifying potential bottlenecks or areas for improvement early on, we can minimize production costs, reduce assembly time, and enhance overall product quality. This proactive approach ensures that your product is designed beautifully and built efficiently for a successful market launch.

Phase 4: Design Validation and Refinement

The final phase of our product design services involves validating and refining the design to ensure it meets market and user expectations. This phase is crucial for finalizing a product that is not only functional but also perfectly aligns with user needs and industry standards.

This includes:

User Testing:

We conduct user testing to gather feedback and identify areas for improvement. Our team employs various testing methods to ensure the product meets user needs and expectations.

- Usability testing

- Focus groups

- Surveys

Design Iteration:

Our product design services team refines the design, incorporating feedback and ensuring the product meets user needs. We iterate on the design until it aligns with the client’s objectives and user requirements.

Final Design Approval:

We are all set for manufacturing once you approve the final design. We ensure all stakeholders are aligned, and the design meets the required specifications, regulations, and quality standards.

Why Partner with a Full-Service Contract Manufacturer for Product Design?

In today’s dynamic market, quickly and effectively launching innovative products isn’t just an edge-it’s essential. Companies that optimize their product development processes are better positioned to respond to rapid shifts in market demands and technological progress. Fortunately, partnering with a full-service contract manufacturer like MFG One for product design services leverages this crucial advantage.

As a product design and development company, we provide numerous advantages in bringing your product to market:

- Integrated Expertise: A contract manufacturing company provides a team of experts across various disciplines, including medical device design and development professionals, ensuring a holistic approach to product design.

- Streamlined Process: With all services under one roof, the design process is more efficient, reducing time-to-market and potential communication gaps.

- Manufacturing Insight: Contract manufacturers bring valuable manufacturing expertise to the design process, ensuring designs are optimized for production from the start.

- Cost-Effectiveness: Considering manufacturing constraints early in the design process can minimize costs associated with late-stage design changes.

- Scalability: Full-service contract manufacturers can support products from initial concept to mass production, providing scalability as demand grows.

- Quality Control: Integrated design and manufacturing services allow for quality monitoring and maintenance throughout the product’s lifecycle.

- Access to Advanced Technologies: Contract manufacturers often invest in cutting-edge design and production technologies, providing clients access to state-of-the-art resources.

Partner with MFG One to Bring Your Revolutionary Product to Market

The journey from concept to a market leader begins with robust and comprehensive product design services. At MFG One, we give you access to our extensive suite of design services powered by our deep manufacturing knowledge.

Our team of skilled designers and engineers will work with you to transform your ideas into market-ready products. We leverage our extensive experience and cutting-edge technologies to deliver innovative solutions that meet your specific needs and market demands.

We serve a diverse clientele and offer reliable product design services nationally and internationally, including but not limited to the USA, the United Kingdom, Canada, and Mexico. If you’re seeking a partner who excels in product design services, reach out to us today!

Request a quote and take the first step toward realizing your vision.