Reverse engineering is a practical tool in a product lifecycle, especially when the original design data is missing, outdated, or inaccessible. By analyzing existing products or assemblies, manufacturers can recover, recreate, or improve functionality while reducing delays caused by obsolete or undocumented parts.

Effective manufacturing connects documentation, verification, and build readiness so recovered designs move straight into controlled production

Table of Contents

Extending Product Life Starts With Accurate Design Recovery

Reverse engineering isn’t limited to repairing broken equipment, it also supports electronic design and manufacturing services in several areas, including:

- Updating aging designs

- Replacing unavailable components

- Exploring new iterations based on proven builds

- Identifying better materials or manufacturing methods to reduce costs

Whether updating an industrial system, a consumer product, or medical technology, this process preserves design continuity, supports long-term serviceability, and ties directly into custom manufacturing services.

The Reverse Engineering Process in

4 Easy Steps

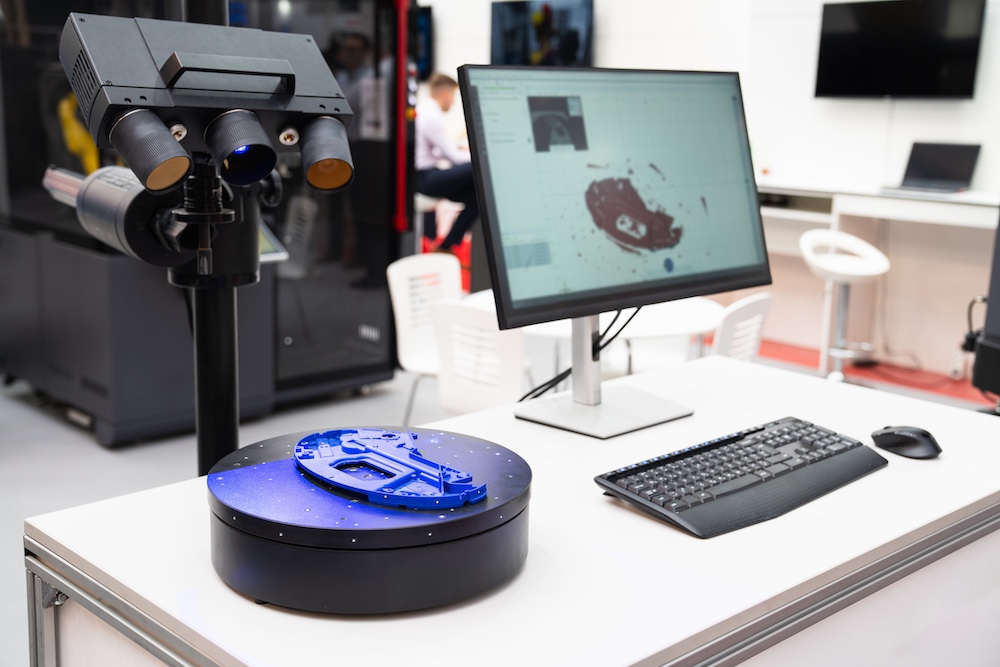

Each reverse engineering project begins with detailed inspection and documentation of the part or system. Teams collect dimensional data, recommend better materials where appropriate, and recreate design intent in a CAD file. The resulting data guides rebuilds or redesigns for manufacturability and consistent quality through:

Step 1: Capture component geometry using 3D scanning and surface mapping

Step 2: Rebuild CAD files and technical drawings based on the scanned data

Step 3: Assess material specs, tolerances, and in-use function

Step 4: Generate final specifications and prepare the part for prototyping and builds

Even well-run manufacturing workflows fold in prototype development services early, so assumptions are validated with real hardware before any decisions are made. This keeps rework low and shortens the path to repeatable builds.

Moving Designs Into Production Flow

Once a design is recovered or recreated, the next step is production, testing, and assembly. The same engineering data supports box build, PCB assembly, harnessing, and system integration.

In many cases, teams transition directly from reverse engineering into turnkey contract manufacturing, with clear handoffs across planning, materials, and validation.

- Turnkey electronic manufacturer capabilities for end-to-end builds

- In-house prototyping for rapid fit/form/function checks

- Testing and functional validation aligned with acceptance criteria

- Assembly and delivery with documented configuration control

To maintain momentum, OEMs rely on manufacturing support services and coordinated logistics to keep production organized, reduce downtime, and maintain predictable schedules. Finished product builds can be shipped through electronic fulfillment services to distribution centers or directly to end users.

Benefits of Reverse Engineering for Modern Builds and Custom Manufacturing

Reverse engineering data often becomes the basis for updated tooling, re-sourcing, or integration into larger systems. It supports consistency across production workflows and aligns parts with current quality or performance standards. By partnering with a box build contract manufacturer that prioritizes traceability and documentation, companies maintain stability and long-term serviceability across the product line.

Organizations also gain options to dual-source risk components and structure alternates in the bill of materials (BOM), supporting turnkey contract manufacturer setups to scale without supply interruptions.

Manufacturing partners that combine CAD recovery, PCB reconstruction, and early prototyping with controlled documentation move faster and help you scale with fewer surprises.

This process translates into specific actions that strengthen manufacturing and product lifecycle management, such as:

- Technical Specification Updates Updated CAD files and documentation improve accuracy and reduce design errors.

- Design and Material Improvements Optimize materials, tolerances, and assembly steps, lowering costs and improving reliability.

- Workflow Integration Recovered parts are adapted to fit within current production processes and ERP/MES records.

- Long-Term Traceability Stored records support audits, repeatability, and lifecycle planning, reducing risks over time.

Supporting Quality, Traceability, and Industry-Specific Builds

Every recovered or revised design through reverse engineering should pass through the same structured quality oversight as newly developed parts. Traceability, performance verification, and documentation remain central, even for legacy or competitor builds.

This discipline is valuable in regulated sectors and time-sensitive markets, including medical, industrial, and high-volume consumer electronics that require fulfillment services at scale.

- Integration with ISO 13485-aligned processes

- Support for FDA-QSR compliance and RoHS builds with serialized tracking

- Quality documentation packaged for audits, change control, or scale-up

- Configuration management that preserves revision history across lots

- Data packages structured for transfer to a turnkey electronic manufacturer if needed

If the route to market includes direct-to-consumer shipments, pairing production handoffs with electronic fulfillment services helps maintain accuracy, warranty tracking, and returns processing.

Reverse Engineering Built Around Your Design Goals

Reverse engineering services bridge the gap between what exists and what’s next. It helps teams maintain product function, adapt to new requirements, and implement targeted design changes without restarting development.

MFG One offers reverse engineering as part of a full-lifecycle approach, helping OEMS move from design recovery to production and ongoing support without disruption. As an electronic contract manufacturer, our goal is to align with your internal processes and provide a clear path from design to high quality production while saving you costs, time and delays.

Our full suite of box build services supports clients across the United States, Canada, the United Kingdom, and Mexico, providing design, manufacturing coordination, assembly, and logistics under one partner.

Request a free quote to connect reverse engineering with turnkey contract manufacturing for your next build.