Aftermarket Services

Strengthen customer confidence and safeguard quality with structured product lifecycle support that extends far beyond the initial build. At MFG One, our overarching aftermarket services are designed to help OEMs maximize asset availability, simplify parts sourcing, and maintain system integrity across the full lifecycle.

Maximize Product Lifecycle Support & Profitability

Rapid Turnaround with Global Reach

U.S.-based facility hub near two major international airports, enabling fast domestic and international logistics.

Full Lifecycle Integration

Seamless transition from custom contract manufacturing services to post-launch support that facilitates serviceability from day one.

Legacy & Current Component Access

Data-Driven Service Records

Built-In Repair, Remanufacturing & Return Management Expertise

Accelerate your reverse supply chain with our end-to-end product lifecycle support. From returns processing to diagnostics, refurbishment, and final redeployment, our processes are traceable, documented, and designed to bolster your long-term product availability.

- Reverse Logistics with RMA Tracking: We coordinate with product returns using system-generated RMA (Return Material Authorizations) and depot-level routing.

- Inbound Screening & Evaluation: Our team inspects returned units to determine warranty status, physical damage, and next action (repair, replacement, or scrap).

- System-Level Fault Isolation: We perform diagnostic testing down to the PCB or component level using product-specific procedures.

- Documented Failure Analysis Reports: We record root cause, repair actions, and field usage data to support product engineering and reliability improvements.

- Refurbishment to Operational Spec: We clean, rework, and re-qualify units to meet original performance benchmarks, including firmware or software updates.

- Box Build Replacements Using Certified Parts: Our product lifecycle support team assembles and tests new or replacement systems using approved BOMs and traceable components.

- Serialized Inventory Tracking: We store, monitor, and rotate repaired units, spare parts, and product inventory with serial-level traceability and usage logs.

- Direct-to-Field or Customer Shipment: As a leading electronic contract manufacturer, we also pack and ship repaired or replacement units to service technicians or end-users using 3PL coordination and shipping compliance protocols.

- Branded and OEM-Agnostic Service Models: We support both in-warranty and out-of-warranty units with clearly defined SLAs and service labeling for consistent turnaround and tracking.

- Legacy Product Continuity: We maintain serviceability of discontinued SKUs through component stocking, remanufacturing plans, and system-level support.

From Product Lifecycle Support to Turnkey Box Builds, We’ve Got It Covered

As a leader in box build manufacturing, MFG One also specializes in product lifecycle support services, delivering fully integrated replacement systems that restore function, extend asset life, and reduce downtime.

Full Systems Integration:

We source PCBAs, wire harnesses, and components through our managed vendor network and perform all box build assembly services in-house. This includes PCB mounting, cable harnessing, grounding, and interconnect integration, each unit built to spec, tested, and ready for plug-and-play deployment.

Customization and Compatibility:

As a key provider of electronic product design and development, MFG One supports customized builds for legacy system replication, product refreshes, or market-specific variants. We match BOMs and configurations precisely, with every design change managed through controlled engineering change order (ECO) processes for backward compatibility and regulatory alignment.

Procurement and Testing:

Our product lifecycle support team handles sourcing of all components, including long lead-time, end-of-life, and high-reliability parts, through vetted suppliers. Each build undergoes final QA, including firmware loading, electrical verification, power-up testing, and mechanical fit checks to validate against design specifications.

Flexible Volumes:

As box build assembly manufacturers, we support low to mid-volume rebuilds for planned field replacements, MRO cycles, and spare inventory programs. Builds can be timed and staged to align with service schedules, fleet updates, or just-in-time delivery strategies to reduce downtime and inventory burden.

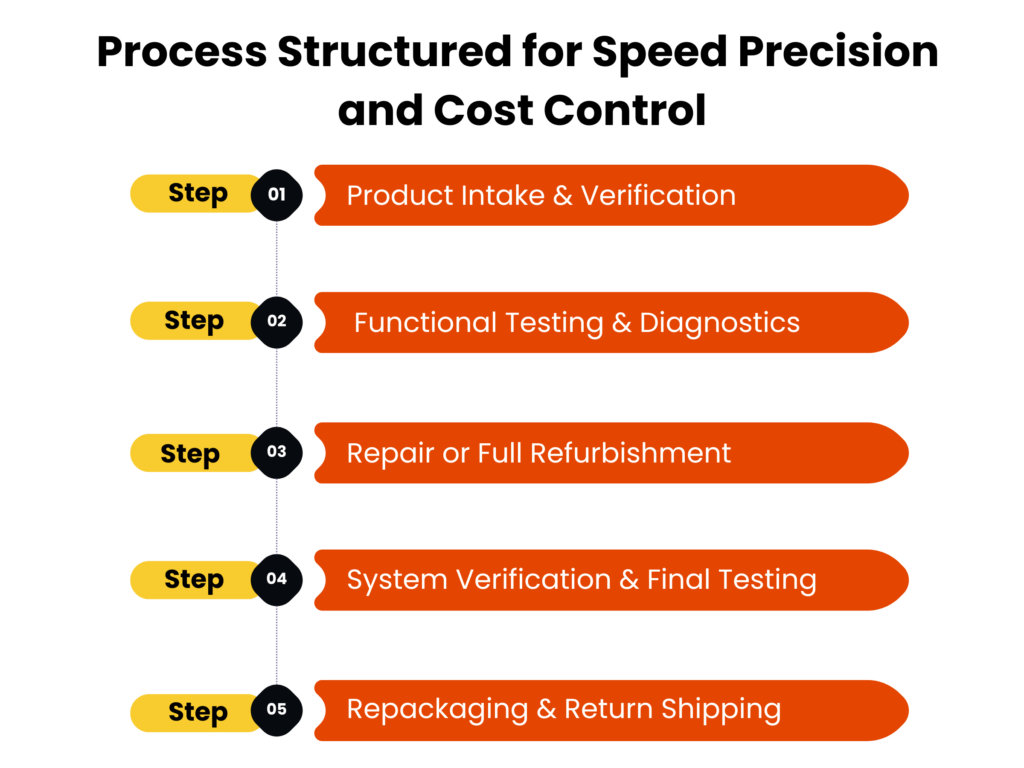

Process Structured for Speed Precision and Cost Control

As part of our 360° contract manufacturing services, we offer a structured repair and refurbishment process built for speed, precision, and cost efficiency.

Step 1: Product Intake & Verification

Step 2: Functional Testing & Diagnostics

Step 3: Repair or Full Refurbishment

Step 4: System Verification & Final Testing

Step 5: Repackaging & Return Shipping

Value Added Services That Simplify Aftermarket Workflows

As a turnkey contract manufacturer, we also specialize in product lifecycle support that streamlines aftermarket operations, reduces internal workload, and improves field readiness.

Bolstering Industries Where Uptime & Performance Are Critical

Aerospace and Defense

Medical and Laboratory

Renewable Energy

Consumer Electronics

Industrial Automation and Robotics

Automotive Manufacturing

Telecom and Networking

Reverse Logistics That Reduce Delays and Simplify Operations

Sustaining product performance after delivery requires more than quick fixes. At MFG One, we apply the same technical rigor to reverse logistics and post-sale service as we do to initial production. Our centralized system for product lifecycle support manages RMAs, triage, and redeployment so your team can focus on supporting customers without being slowed down by operational complexity.

Returned units are matched against approved RMAs, verified for part and serial numbers, and entered into the tracking system for traceability.

Each unit is inspected for physical condition, assessed for urgency or warranty status, and routed to the appropriate repair path.

Progress is tracked in real time or shared through scheduled updates, with technician assignment and turnaround estimates provided.

Repaired or replacement units are repacked with updated labels, documentation, and any customer-specific shipping requirements.

A detailed report is created for each unit, covering diagnostics, parts replaced, test results, and corrective actions taken.

Let’s Build Your Aftermarket Strategy Together

MFG One is a reputed contract manufacturer in USA that has been serving both domestic and international markets since 2001, including Canada, the United Kingdom, Mexico, and beyond. We bring the same disciplined approach to product lifecycle support we apply to production, helping OEMs reduce service lead times, improve customer satisfaction, and extend system performance over the long term.