Table of Contents

How Design and Engineering Services Develop and Refine Market-Ready Products

- Product Design and Engineering: Developing designs that merge functionality and aesthetics while meeting regulatory and market requirements.

- Mechanical and Electrical Engineering: Creating systems and components that operate efficiently, focusing on usability and reliability.

- Prototyping and Optimization: Producing models that test functionality, identify potential issues, and refine the product for manufacturing.

- Compliance and Testing: Integrating processes that follow industry standards for safety and quality, reducing risks before production.

By investing in a contract manufacturer’s expertise in areas like product engineering and design, as well as prototype development, these solutions bridge the gap between concept and commercialization, driving innovation while maintaining practicality.

Core Stages in Design and Engineering

- Stage 1: Concept Development

This initial stage defines the purpose and vision of the product. It involves brainstorming ideas, conducting feasibility studies, and drafting early designs to lay a strong foundation for the project. - Stage 2: Feasibility Analysis

Technical and market feasibility are evaluated to confirm that the concept aligns with real-world demands, production capabilities, and cost considerations. - Stage 3: Prototyping and Testing

Early prototypes are developed to test functionality, usability, and durability. This phase identifies areas for refinement and makes sure the design is practical for manufacturing. - Stage 4: Design Refinement

Based on prototype feedback, adjustments are made to improve performance, streamline production, and address any potential issues. - Stage 5: Production-Ready Design

The final stage involves preparing detailed designs for manufacturing and optimizing for efficiency, scalability, and quality.

These stages not only improve collaboration between teams but also integrate critical aspects of engineering and design services to deliver innovative, functional, and market-ready products.

Why Partnering with a Design and Engineering Service Provider Improves Product Development

- Access to Expertise: Benefit from specialists in mechanical and electrical engineering who design solutions optimized for performance, usability, and manufacturability.

- Improve Product Functionality: Refined designs and early problem-solving lead to better-performing, user-focused products.

- Risk Mitigation: Expertise in regulated industries, such as medical device manufacturing and compliance, helps prevent costly errors during development.

- Faster Timelines: Efficient workflows, sustainable engineering, and prototype development services help reduce time-to-market, giving businesses a competitive edge.

- Scalability: Partners experienced in commercial manufacturing and assembly can help scale production efficiently, meeting both small and large-volume demands without compromising quality.

By partnering with experienced contract manufacturing providers, businesses can concentrate on their core operations while the experts handle the complexities of design, testing, and production, creating greater efficiency and success in developing the product.

How Design and Engineering Services Reduce Time to Market

Speed and precision are critical for gaining a competitive edge. By integrating design and engineering services, businesses can streamline the entire product development cycle, accelerating the delivery of functional, high-quality products to market.

Here’s how these product development services drive faster timelines:

- Efficient Concept Development: Experts refine initial ideas into actionable blueprints, minimizing delays and creating a strong foundation for development.

- Rapid Prototyping: Prototype development services allow teams to quickly create and test models, identifying improvements and addressing potential issues early.

- Integrated Workflows: Seamlessly combining product assembly services and engineering expertise reduces bottlenecks during production.

- Regulatory Alignment: Professionals knowledgeable in medical device design and manufacturing address compliance requirements with expertise to avoid roadblocks during approvals.

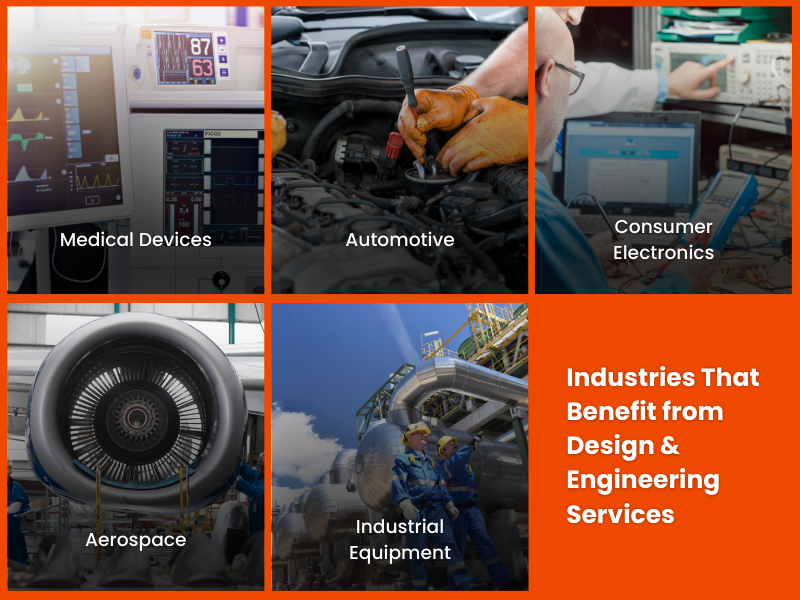

Industries That Benefit from Design and Engineering Services

Design and engineering services are integral to manufacturing across a wide range of industries, addressing unique challenges and enabling innovation. Here’s a closer look at how these services are applied in different sectors:

- Medical Devices: From concept development to product design and engineering, these services enable the creation of safe, functional, and user-friendly devices tailored to healthcare needs.

- Automotive: Optimizing commercial manufacturing and assembly, design experts help produce components for vehicles that prioritize performance and efficiency.

- Consumer Electronics: Fast prototyping and streamlined workflows allow companies to launch cutting-edge gadgets that meet market demands.

- Aerospace: Precision-focused engineering manufacturing services maintain the reliability and functionality of components in critical applications.

- Industrial Equipment: Supporting machinery development with engineering and design, these solutions enhance operational efficiency and durability.

By addressing the unique requirements of various industries, design and engineering services enhance production efficiency while upholding the quality and standards needed for success in highly regulated environments. This adaptability makes these services an indispensable asset for businesses striving to create competitive, market-ready products.