New Product Introduction Services

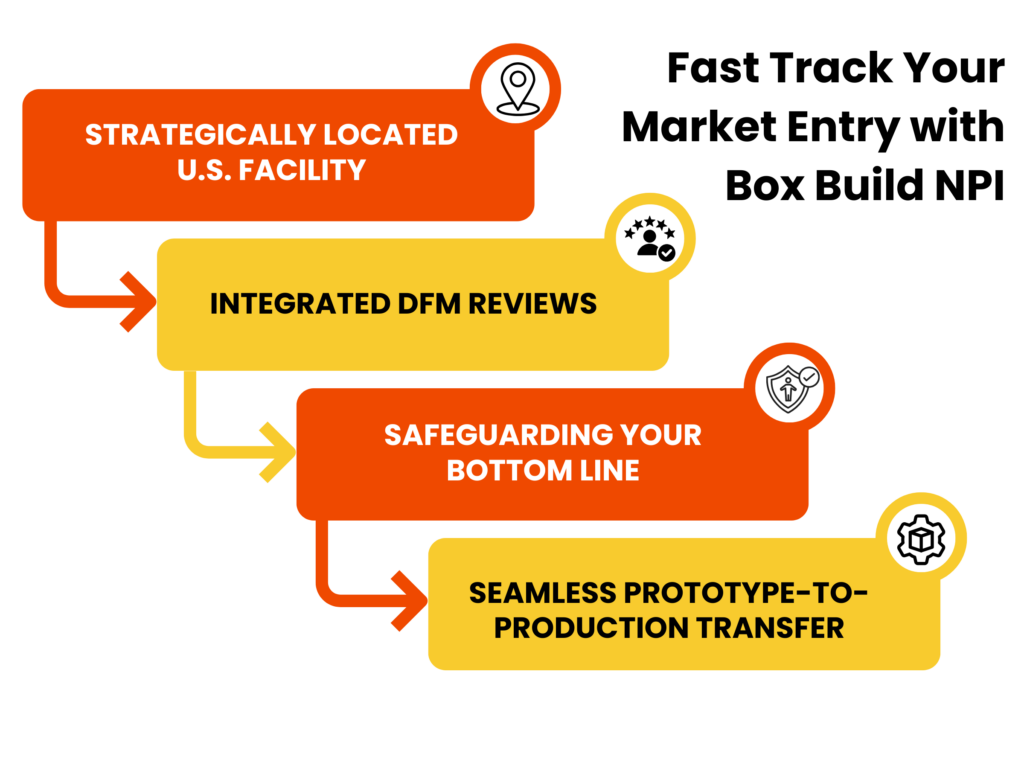

Fast Track Your Market Entry with Box Build NPI

We assist you with our in-house box build assembly and supply chain support. By integrating design feedback, pilot builds, and production transfer into a seamless, risk-controlled process, we help you focus on core business activities.

Hands-on coordination, aftermarket services and pilot-build solutions with easy access to major international airports.

Design-for-Manufacturing feedback built into every phase to identify risks early along with structured documentation and traceability standards.

We reduce waste, compress lead times and streamline sourcing to deliver high-quality outcomes with measurable cost savings.

As a leader in custom contract manufacturing services, we manage production with no disruption to configuration, quality, or timelines.

Design Review and Risk Mitigation Before the First Build

At MFG One, we go beyond surface-level design checks. Our team of adept engineers spearheads the development of manufacturable, testable, and cost-optimized products from the ground up. With our new product introduction services, we identify issues like poor test access, high-risk components, and assembly friction before they reach the floor, so your first build moves forward uninterrupted.

- Co-design partnerships: Collaborating early on board layout, mechanical fit, and production methods to avoid preventable changes later.

- Design for Excellence (DfX): Applying focused design input for quality control, cost targets, and industry-specific compliance needs.

- Design for Assembly (DFA): We design with assembly in mind, simplifying fasteners, cable routing, and part interfaces to streamline builds and reduce time at the bench.

- Design for Cost (DFC): Analyzing trade-offs between materials, form factor, and complexity to keep cost targets on track.

- DFM and DFT Reviews: Identifying weak points in the assembly process and test access limitations before they impact your schedule.

- Component Risk Analysis: Spotting long lead-time, high-failure, or EOL parts early and suggesting approved replacements with sourcing advantages.

- Tooling and Fixture Planning: Defining the mechanical and electrical tools needed for consistent builds, starting at the design phase.

- Test plan development: Aligning in-circuit, functional, and final-system testing requirements before production starts

- Continuity testing: Verifying cable assemblies, PCB interconnects, and wiring harnesses for electrical integrity and pin-to-pin accuracy

Prototyping and Early Builds Using Production-Grade Infrastructure

With our advanced new product introduction services, we produce your prototypes and initial builds using the same calibrated equipment, quality systems, and controlled workflows used in box build manufacturing. This approach makes sure that what passes in development won’t need rework or redesign later, thus reducing risk, shortening the path to validation, and facilitating volume manufacturing.

Turnkey PCB manufacturing from our wide-network of vendors including building both low-volume SMT and through-hole PCBAs.

Early unit builds include full system integration for enclosure fit, cable routing, and interconnect validation.

Components are procured through qualified supply chain channels to mirror production sourcing and availability.

Every unit undergoes electrical validation and test coverage at the board or system level.

Clean documentation, revision control, and serial tracking are maintained to enable downstream QA and compliance.

A Scalable New Product Introduction Service Process for Complex Electronic Products

As a leading provider of electronics manufacturing services through advanced vendor-partnerships, MFG One helps you move from prototype to market entry with a structured, phase-based approach. Each stage is built to reduce rework, shorten timelines, and facilitate long-term product performance.

Design Alignment and Risk Reduction

We collaborate early to refine designs for manufacturability and test coverage. Our team reviews BOMs to identify sourcing risks and lifecycle concerns, while also building regulatory-ready documentation aligned with FDA-QSR and ISO 13485:2016 standards.

Build and Validate Early Units

As part of our EMS contract manufacturing process, we verify early units using production-grade tools, materials, and QA processes. Functional and in-circuit test strategies are developed up front, followed by pilot builds to validate yield, process flow, and test coverage.

Transition to Full Production

After pilot builds are validated, we shift into volume production using proven workflows through our new product introduction services. Vendor coordination and production planning are tightly managed to bring repeatability and schedule consistency.

Post-Launch Support and Lifecycle Management

We offer aftermarket services including repair, refurbishment, and global distribution support. With 3PL coverage in the US, Canada, the UK, and Mexico, we help extend product life while maintaining technical continuity across deployments.

Regulatory Support and Product Documentation Management

At MFG One, regulatory alignment isn’t treated as a separate task; it’s embedded into every phase of our manufacturing process. Whether you’re preparing for an FDA inspection, ISO audit, or industry-specific review, our new product introduction services help you with documentation that is complete, traceable, and compliant from initial design through final release.

Design History File (DHF) Management

Capturing all design inputs, changes, reviews, and approvals in a structured, inspection-ready format.

ISO 13485:2016 & ISO 9001-Aligned Workflows

Mapping processes directly to certified quality system standards, supporting consistency and regulatory adherence.

BOM Traceability & Change Control

Maintaining full visibility into part sourcing, revision history, and engineering changes with documented approvals.

Verification & Validation Documentation

Generating formal test reports, inspection records, and analysis logs and maintaining them as part of the build process.

Device Master Record (DMR) Assembly

Compiling complete DMR packages to bolster medical device new product development requirements.

Industries We Support

Our new product introduction services are built for product teams working in industries where traceability, speed and production readiness matter from the start.

We Bridge Development & Full-Scale Manufacturing

At MFG One, we provide a structured handoff between product development and in-house box build assembly services. Once a prototype is approved, we initiate controlled pilot runs designed to validate every critical aspect of the build — yield performance, test coverage, material flow, and assembly repeatability. These early-stage builds help identify potential process risks, verify tooling and fixture performance, and maximize alignment between engineering intent and manufacturability.

By the time a product reaches production volumes, our team has already refined the workflow, locked in the BOM and test procedures, and confirmed system reliability under real-world conditions. Our new product introduction services are appreciated by OEMs worldwide to ramp-up friction, shorten lead times, and provide them with the confidence that their product will scale without unexpected delays or inconsistencies.

Let’s Build a Launch Plan Customized to Your Next Product

As a contract manufacturer in the USA, we partner with OEMs across the United States, Canada, the United Kingdom, Mexico, and other international markets to support product introductions in fast-moving and highly technical environments. Ready to move forward? Connect with our team or share your project brief to get started.