FDA Registered & ISO 13485 Contract Manufacturer

MFG One is an ISO 13485 contract manufacturer in the USA applying strict process control and certified systems to deliver consistent product performance across design, production, and aftermarket support.

Our Hands-On Approach to Material and Logistics

As a reputed US-based ISO 13485 contract manufacturer, we put our minds, years of expertise, and industry-approved standards to every build. We have rigorous quality protocols integrated into every phase of the product lifecycle. From prototyping and new product introduction (NPI) to full-scale supply chain management, our consistency and integrity are second to none.

And with each passing day, we’re making our custom manufacturing and engineering processes more proactive, repeatable, and traceable across every function and build.

A Quality-first Approach Across Every Product Build and Service

ISO-Certified Systems

Full documentation, audit trails, and compliance with ISO 13485, FDA-QSR, and other applicable standards.

Early QA Integration

Quality engineering engaged in electronic product design and development including DFM/DFA and NPI.

Transparent Pricing

Cross-Functional QA & Manufacturing

Certifications That Validate Our Systems and Your Confidence

Regulated markets demand more than quality. They require documented systems, consistent execution, and proof of compliance. MFG One is a proud US-based contract manufacturing partner that meets these expectations with credentials that demonstrate our ability to manufacture, inspect, and distribute high-reliability products in tightly controlled environments.

ISO 13485:2016

ISO 13485 contract manufacturer capable of developing medical devices with robust quality controls and risk management.

FDA Facility Registration

Authorizes us as a medical device manufacturer in accordance with U.S. FDA-QSR regulations.

Louisiana Board of Drug and Device Distributors Certification

Allows regulated device distribution in Louisiana.

Virginia Board Pharmacy Permit

Permits device distribution within Virginia under state pharmacy laws.

Get Regulatory Guidance & Compliance Support From an ISO 13485 Contract Manufacturer

Meeting regulatory expectations starts with the right systems and extends through every phase of product development. As a leading ISO 13485 contract manufacturer in the USA, MFG One provides direct, experienced support to help you navigate complex compliance requirements with clarity and control so that your product easily fits both technical and regulatory demands.

Our Custom Contract Manufacturing Services Come With:

We assist in preparing structured, complete documentation for FDA review, aligning with ISO 13485 protocols to facilitate smoother approvals in medical device design manufacturing.

Our team guides you through the Nationally Recognized Testing Laboratory (NRTL) process for North American electrical safety compliance, from technical file creation to lab coordination.

We manage and maintain accurate DHF, DMR, and related files to support audits, inspections, and ongoing compliance.

Component and material sourcing is handled with full alignment to global environmental directives, supporting market access and regulatory assurance.

We assist in preparing and submitting documentation for FDA review, helping to streamline approvals through our ISO 13485-aligned processes.

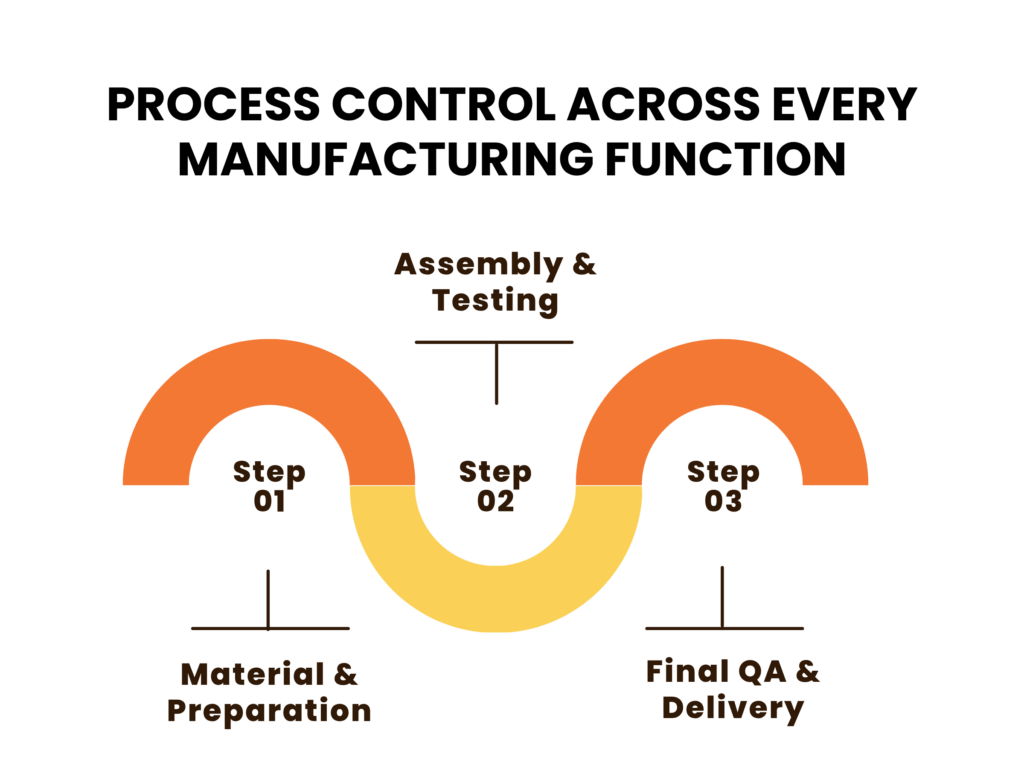

Process Control Across Every Manufacturing Function

When your product is a life-saving device, an automotive system, or part of a critical infrastructure network, you deserve full confidence in its performance.

At MFG One, we’ve maintained nearly a decade of consecutive clean audits by focusing on what matters: every part, every step, every outcome. Our ISO 13485-certified workflows cover everything from incoming materials to 3PL warehouse services, built for traceability, accuracy, and quality at scale.

- Incoming Material Inspection: Part number verification, visual, and mechanical checks

- SMT and Assembly Validation: Repeatable setups, first-article confirmation, and controlled line changes

- In-Process Quality Checkpoints: Inspections at key stages, including during PCB box build assembly services, to maintain quality throughout production.

- Functional and In-Circuit Testing: Validation using customer-specific procedures and test protocols.

- Box Build QA: Full-system checks including firmware loading, power-up tests, and labeling.

- Final Audit and Packaging Review: Conformance to packaging specifications, labeling, and shipment documentation.

Let’s Talk About Your Product Requirements

Partner with an ISO 13485 contract manufacturer that brings structure, clarity, and technical control to every phase of your product lifecycle. At MFG One, we don’t just follow your build requirements; we integrate them into disciplined, documented processes that bring traceable, repeatable results.

Whether you’re launching a first prototype, scaling to high-volume production, or navigating supply chain intricacies, our quality systems are built to align with your goals and timelines. Our contract manufacturing services cater to both national and international markets, including the United States, Canada, the United Kingdom, Mexico, and beyond.

We’re ready to support your build from the first design review through final shipment, with the same attention to detail at every step.