As a leading medical devices product development company, MFG One is your partner in understanding and meeting these requirements. This comprehensive guide will walk you through the critical regulatory milestones and provide actionable tips to streamline your path to approval.

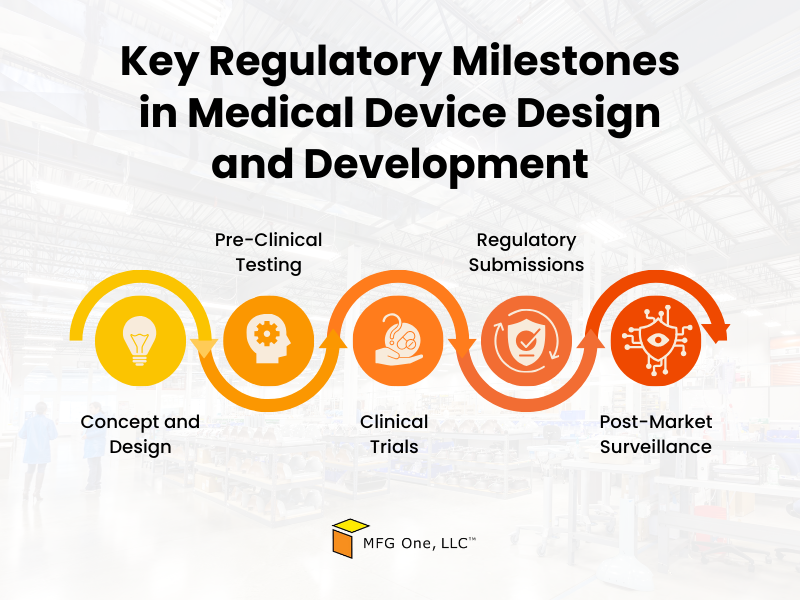

Key Regulatory Milestones in Medical Device Design and Development

1. Concept and Design

- Define your device’s intended use, target patient population and key features. A well-articulated concept is the cornerstone of effective medical device design and development.

- Identify potential hazards associated with your device and develop robust mitigation strategies to ensure patient safety. A comprehensive risk assessment is critical for demonstrating the device’s safety profile to regulatory authorities.

- Establish robust design controls, including document management, design reviews, and change control processes, to ensure your design meets safety and performance requirements.

- Engage regulatory experts early to align your medical device design and development with applicable standards (e.g., ISO 13485, IEC 60601) and regional/country-specific regulations.

2. Pre-Clinical Testing

This may include mechanical testing, electrical safety testing, software validation, and usability testing. Analyze the test data meticulously to identify and address potential issues before proceeding to clinical trials.

This may include mechanical testing, electrical safety testing, software validation, and usability testing. Analyze the test data meticulously to identify and address potential issues before proceeding to clinical trials.

3. Clinical Trials (if applicable)

Clinical trials are often a pivotal step in medical device design and development, particularly for Class III devices or those with significant risks. For good clinical practice, your clinical trial design should align with regulatory guidelines.

Carefully select trial sites and investigators with relevant expertise. Obtain informed consent from all trial participants. Collect comprehensive data on safety and effectiveness throughout the trial and adhere to strict data integrity standards.

4. Regulatory Submissions

Prepare a comprehensive regulatory submission package tailored to the specific requirements of your target market. For the US market, this typically involves submitting a 510(k) premarket notification or a Premarket Approval (PMA) application to the FDA.

Your submission should include detailed documentation of your medical device design and development process, manufacturing processes, testing results, risk management plans, and labeling information. Collaborate closely with regulatory experts to ensure your submission is complete, accurate, and meets all regulatory standards.

5. Post-Market Surveillance

Once your device receives regulatory approval, your responsibility for compliance continues. Implement a robust post-market surveillance program to monitor the device’s performance in real-world settings.

This involves collecting and analyzing data on adverse events, complaints, and device malfunctions. Promptly report any safety concerns to regulatory authorities and take appropriate corrective actions to ensure your device’s continued safety and effectiveness.

Tips for a Smooth Regulatory Journey

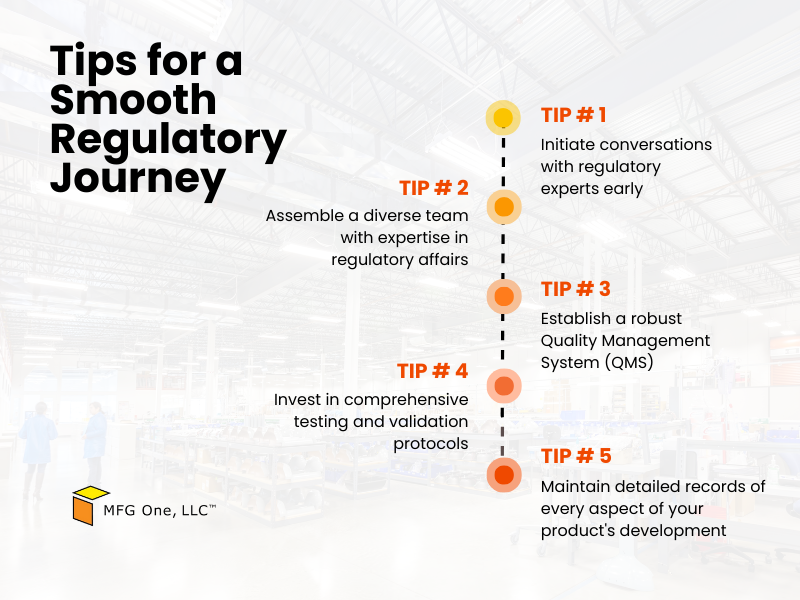

- Engage Early and Often: Initiate conversations with regulatory experts early in the medical device design and development process to align your development efforts with regulatory requirements. Ongoing communication with regulatory agencies can help you anticipate and address potential roadblocks.

- Assemble a Multidisciplinary Team: Successful medical device development requires a diverse team with expertise in regulatory affairs, quality assurance, engineering, clinical research, and marketing. Collaboration among these disciplines is essential for navigating the complex regulatory landscape.

- Establish a Robust Quality Management System (QMS): A QMS is the backbone of regulatory compliance. It ensures consistent quality in all aspects of medical device design and manufacturing, from design controls to document management, risk management, and supplier control.

- Prioritize Testing and Validation: Invest in comprehensive testing and validation protocols to generate robust data that demonstrates your device’s safety and effectiveness. This includes both pre-clinical and clinical testing, as well as ongoing post-market surveillance.

- Document, Document, Document: Meticulous documentation is crucial for regulatory compliance. Maintain detailed records of every aspect of your product’s development, including design decisions, testing results, risk assessments, and manufacturing processes. Well-organized documentation will facilitate regulatory submissions and audits.

How Contract Manufacturing Can Expedite Regulatory Approval

Partnering with a medical device contract manufacturing company can be a strategic move to accelerate your regulatory approval process. Here’s how:

- Regulatory Expertise: Experienced FDA-registered medical device manufacturers like MFG One have in-depth knowledge of regulatory requirements and a proven track record of successful submissions. They can guide you through the intricacies of the regulatory process, ensuring your device meets all necessary standards.

- Streamlined Processes: Contract manufacturers have established processes and systems to streamline medical device design and development. This can significantly reduce the time and resources required to bring your product to market.

- Quality Assurance: Reputable contract manufacturers adhere to strict quality standards and have robust quality management systems in place. This ensures that your device is manufactured to the highest quality standards, reducing the risk of regulatory setbacks.

- Experience and Resources: Contract manufacturers have a wealth of experience in developing and manufacturing medical devices. They have access to specialized resources, including testing facilities and regulatory experts, that can help you navigate the regulatory landscape more efficiently.

Achieve Regulatory Compliance in Your Medical Device Design and Development with MFG One

At MFG One, we are more than just a contract manufacturer in the USA. We are a medical device product development company committed to your success. Our comprehensive product design and development services, including engineering and design services, prototyping, manufacturing, and quality assurance, can help you handle complex regulations and bring your innovative medical device to market.

With a global presence in the US, Canada, United Kingdom, Mexico, and beyond, we are equipped to support your medical device new product development needs wherever you are located.

Contact us today to learn how we can partner with you to achieve your regulatory and commercial goals.