Struggling to balance soaring production costs with the demand for rapid product launches? Outsourcing product assembly services can be your solution. This strategic move empowers businesses to enhance profitability, improve product quality, and gain a competitive edge. This blog looks at the top seven benefits of outsourcing product assembly services to a full-service contract manufacturer and how they can transform your business.

#1. Cost Reduction and Efficiency

Effective cost management is a cornerstone of business success, and outsourcing electronic design and development can lead to substantial financial savings. By leveraging the economies of scale and specialized labor from product assembly services, your business can significantly reduce operational costs while enhancing overall efficiency.

- Lower Labor Costs: Outsourcing product assembly services can substantially cut labor expenses. This eliminates the need to recruit, train, and maintain a skilled in-house workforce, redirecting those resources to fuel business growth and innovation.

- Reduced Overheads: By eliminating the need for in-house assembly facilities, you can significantly reduce fixed costs such as rent, utilities, equipment maintenance, and facility management. This frees up capital for strategic initiatives and operational improvements.

- Optimized Resource Allocation: Outsourcing allows your business to focus resources on core competencies, leading to increased productivity and efficiency. By streamlining operations and eliminating non-core activities, your business can achieve faster turnaround times and improve overall performance.

#2. Focus on Core Competencies

When outsourcing product assembly services, you can redirect resources to high-value activities that drive innovation and growth. Focusing on your core competencies can strengthen your market position and increase your competitiveness.

Here’s how:

- Strategic Alignment: Delegating product assembly frees internal teams to concentrate on product design and development, innovation, and marketing – directly contributing to revenue growth. Companies can differentiate themselves in the market by focusing on core competencies and building a stronger competitive position.

- Improved Resource Allocation: By delegating assembly tasks, you can allocate resources more effectively, prioritizing high-value activities. This enables you to redirect resources to strategic initiatives, optimize efficiency, and focus on high-impact projects while streamlining operations and enhancing bottom-line performance.

- Enhanced Innovation: Focusing on core competencies can lead to increased innovation and competitiveness. Concentrating on what you do best can drive innovation, improve electronic product design and development, and enhance your market position. Additionally, this focus allows you to stay ahead of industry trends and respond quickly to changing customer needs, ultimately leading to sustained growth and success.

#3. Scalability and Flexibility

In a constantly changing market, the ability to scale and adapt quickly is key to staying competitive. Outsourcing your product assembly services provides the flexibility you need to adjust production levels in real-time, ensuring that your resources are used wisely and efficiently.

- Demand Fluctuations: Outsourcing provides the flexibility to scale assembly operations up or down to meet fluctuating demand, preventing overstaffing or underproduction. This helps your team to avoid costly inventory buildups or production shortages.

- Rapid Growth: With rapid business expansion, outsourcing can quickly accommodate increased production needs without significant capital investment. By partnering with a flexible contract manufacturer in the USA, you can scale your operations to support growth and seize new opportunities.

- Seasonal Variations: For businesses with seasonal product demand, outsourcing offers a cost-effective way to manage fluctuating production requirements. You can optimize resource utilization and avoid idle capacity during off-peak seasons by aligning production with demand.

#4. Access to Expertise and Technology

Partnering with a full-service contract manufacturer opens the door to specialized expertise and cutting-edge technology that might be out of reach in-house. This collaboration can elevate your product’s quality and operational efficiency to new heights.

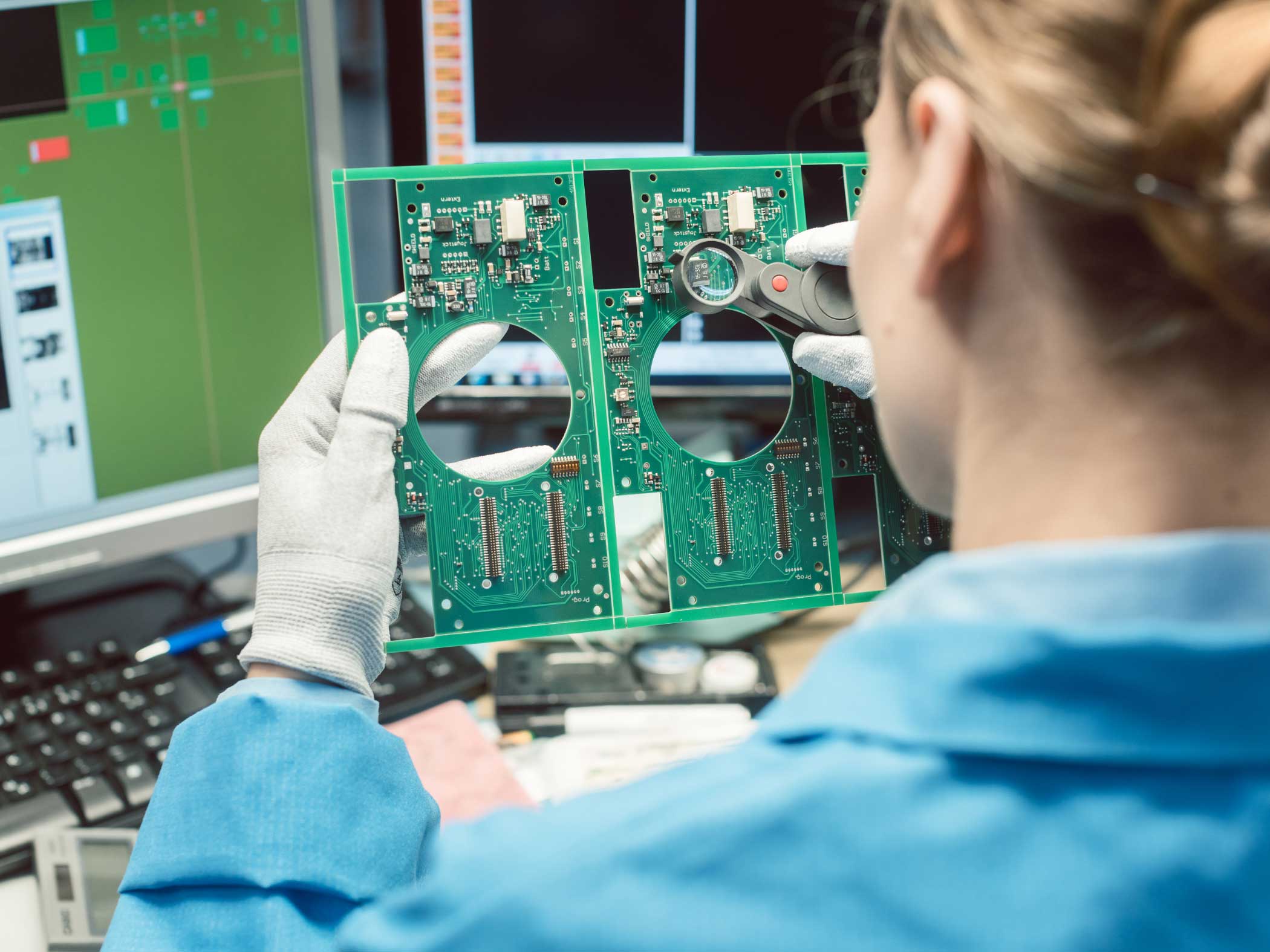

- Specialized Skills: Outsourcing gives you access to product assembly service providers with deep expertise in specific assembly areas. This means your products benefit from industry best practices and expert knowledge that enhance their performance and reliability.

- Advanced Technology: Product assembly experts typically invest in cutting-edge assembly equipment and technologies, ensuring optimal efficiency and product quality. Access to these advanced technologies can help improve product performance and reduce production costs.

- Continuous Improvement: Partners often have established quality control processes and lean manufacturing practices, leading to continuous improvement in assembly operations.

Collaborating with a product design and development company focused on process optimization can improve efficiency and reduce defects.

#5. Reduced Risk and Liability

Running a successful business means effectively managing risks. Outsourcing product assembly services can mitigate potential challenges by transferring some responsibilities to a specialized provider, allowing you to focus on your core strengths.

- Supply Chain Resilience: Outsourcing can mitigate supply chain risks by partnering with established manufacturers who have contingency plans in place to address potential disruptions. This ensures your production remains on track despite unforeseen circumstances, providing peace of mind and safeguarding your business operations.

- Compliance Adherence: Assembly providers are typically well-versed in industry regulations and standards, reducing non-compliance risk. You can avoid costly penalties and reputational damage by partnering with a compliant assembly provider.

- Mitigated Risk of Product Defects: Outsourcing product assembly services to experienced manufacturers reduces the risk of costly product defects and recalls. They have robust quality control processes, including documentation, validation, and testing protocols, ensuring your products meet the highest standards and minimizing potential liabilities.

#6. Faster Time-to-Market

Speed is crucial in today’s market. Being first to market can give you a significant edge over your competitors. Outsourcing product assembly services can accelerate your production timelines, allowing you to introduce new products more quickly and effectively.

- Accelerated Production: Specialized providers of product assembly services have streamlined processes and optimized workflows, resulting in faster production times. You can reduce lead times and increase product availability by leveraging the assembly provider’s expertise.

- Reduced Lead Times: Outsourcing can significantly shorten lead times and improve order fulfillment by eliminating internal bottlenecks. Faster order fulfillment can enhance customer satisfaction and loyalty.

- Market First-Mover Advantage: Faster time-to-market enables businesses to gain a competitive advantage by introducing new products sooner. By being the first to market with a new product, you can capture early market share and build brand awareness.

#7. Improved Quality and Customer Satisfaction

Delivering high-quality products is essential for maintaining customer satisfaction and building a solid brand reputation. Outsourcing product assembly services can improve quality control processes, ensuring your products consistently meet or exceed customer expectations.

- Quality Control Focus: Assembly providers have dedicated quality control teams and processes to ensure product excellence. By partnering with a quality-focused assembly provider, your business can improve product consistency and reduce defects.

- Consistent Quality: Outsourcing product assembly services can lead to more consistent product quality due to standardized procedures and an experienced workforce. Consistent product quality enhances customer satisfaction and builds brand trust.

- Enhanced Customer Satisfaction: Improved product quality and faster delivery times increase customer satisfaction and loyalty. Delivering high-quality products on time can strengthen customer relationships and drive repeat business.

Choosing the Right Product Assembly Partner

Selecting the right assembly partner is crucial for maximizing the benefits of outsourcing the product assembly service. A well-chosen partner can make all the difference in achieving your business goals and ensuring a successful collaboration.

- Expertise and Experience: Look for an electronics prototype company with a proven track record in your industry and with similar product complexity. An experienced partner can bring valuable insights and best practices to the table.

- Quality Standards: Verify the partner’s quality control processes and certifications to ensure product excellence. A partner with a strong quality focus can help maintain high product standards.

- Capacity and Scalability: Assess the contract manufacturer’s ability to handle your current and future production needs. A flexible partner can accommodate changes in demand and support business growth.

- Location and Logistics: Evaluate the partner’s proximity to your target markets and their logistics capabilities. A strategically located engineering and design services team can help reduce transportation costs and lead times.

Contact MFG One for Unmatched Product Assembly Services

MFG One is a leading provider of medical device design and manufacturing services with a proven track record of delivering exceptional results. Our expertise, state-of-the-art facilities, and commitment to customer satisfaction make us the ideal partner for your assembly needs.

Our Virginia facility is strategically located near major airports and transportation hubs, providing streamlined logistics and efficient delivery for clients across the USA, the United Kingdom, Canada, and Mexico. We provide contract manufacturing services to national and international clients, ensuring timely and cost-effective solutions for your product assembly needs.

If you’re ready to outsource your product assembly services, contact MFG One today to discuss your specific needs and get a free consultation.