From life-saving equipment to everyday healthcare tools, medical devices are only as good as the electronics inside them. This is where contract electronics manufacturing services step in.

By partnering with an experienced electronics manufacturer, medical device companies can bring cutting-edge technology to market faster and more efficiently.

Whether you’re developing a complex diagnostic machine or wearable health monitors, contract electronics manufacturing services allow you to focus on innovation while leaving the technical complexities to the experts.

In this blog, we’ll explore how these services fuel medical device innovation and what to look for when selecting a partner.

Importance in Medical Device Development

Contract electronics manufacturing services provide the technical foundation that allows medical innovations to come to life. From concept to commercialization, electronic product engineering and design play a critical role in making devices functional, reliable, and compliant with industry standards.

Here’s why they matter:

- Precision and Reliability: Medical devices must perform consistently, and that starts with high-quality electronics.

- Regulatory Compliance: In the medical field, compliance with strict regulations is non-negotiable. A contract electronics manufacturer helps make sure that your device meets necessary standards, such as FDA regulations in the U.S.

- Scalability: Whether you’re developing a few prototypes or preparing for mass production, contract electronics manufacturing services allow for scalability without sacrificing quality.

By partnering with a provider who understands the specific needs of medical technology, you can streamline development while making sure that your devices meet the highest standards of safety and performance.

Types of Electronics in Medical Equipment

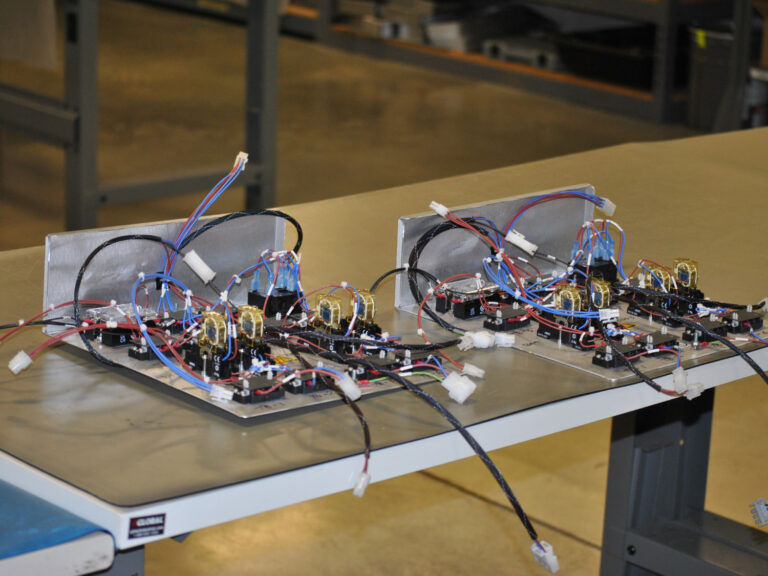

It’s well known that medical devices rely on advanced electronics to perform critical functions. These components, integral to electronic product design and development, work together to maintain the accuracy, reliability, and safety of healthcare technology. When you work with a contract electronics manufacturing service provider, you gain access to expertise in integrating these critical elements.

Some common types of electronics found in medical devices include:

- Sensors: Detect and monitor physical changes like heart rate, temperature, or blood pressure.

- Circuit Boards: Serve as the backbone of most medical devices, connecting different components for seamless functionality.

- Microcontrollers: Manage the operations of medical devices, enabling them to process data and execute functions automatically.

- Power Management Systems: Assure that devices operate efficiently while conserving battery life, especially in portable medical equipment.

- Communication Modules: Enable devices to transmit data to healthcare systems or other medical equipment for real-time monitoring and analysis.

Each of these components plays a vital role in creating advanced, reliable medical devices. With the right contract electronics manufacturing services, you can integrate these electronics smoothly into your product design.

Quality and Compliance in Medical Electronics

The healthcare industry demands absolute precision, and your electronics partner must be up to the task. That’s why contract electronics manufacturing services are key players in this space-they bring both technical expertise and a deep understanding of regulatory requirements.

Here’s what makes these services a top choice when investing in medical electronics:

- Precision Manufacturing: In the medical world, there’s no room for error. Every component is manufactured with the utmost care to meet the strict standards required for patient safety.

- Regulatory Knowledge: Partnering with a provider who understands industry regulations, like FDA requirements in the U.S. and ISO certifications, can help you avoid common compliance headaches.

- Thorough Testing: Manufacturing process validation, quality checks, and testing are integrated into the manufacturing process, giving you peace of mind that your devices are ready for real-world application.

With the right contract electronics manufacturing services, your medical devices will be designed and produced to meet industry standards, making sure they are safe, reliable, and ready for the market.

Speeding Time-to-Market: How Contract Manufacturing Accelerates Production

The medical industry is incredibly fast-paced, and getting your product to market quickly can be the difference between success and missed opportunities. This is where contract electronics manufacturing services excel, helping you accelerate production timelines without sacrificing quality.

Here’s how they make it happen:

- Streamlined Processes: By integrating design, engineering, and production under one roof, EMS contract manufacturing cuts out unnecessary delays, moving your product from prototype to production faster.

- Scalability: Whether you need a limited production run or full-scale manufacturing, these services are flexible enough to handle your needs as they evolve.

- Access to Expertise: With product assembly services and a dedicated team of engineers, you gain access to specialized knowledge that speeds up decision-making and reduces time-consuming revisions.

- Cutting-Edge Technology: Modern contract manufacturers use advanced technologies like automated assembly and rapid prototyping, helping you stay ahead of the competition and meet market demand.

Partnering with a trusted contract electronics manufacturing service provider gives you the speed and agility you need to bring innovative medical devices to market in record time.

Finding a Contract Manufacturer Who Can Support Innovation

Choosing the right partner for contract electronics manufacturing services is critical, especially when innovation is at the heart of your business. A great contract manufacturer not only provides technical expertise but also collaborates with you to push the boundaries of what’s possible in medical technology.

Here’s what to look for in a partner:

- Industry Experience: Look for a manufacturer with a proven track record in the medical device industry. They’ll have the knowledge to anticipate challenges and offer creative solutions.

- Flexibility in Design and Production: Your manufacturing partner should offer product design services that can adapt to evolving product designs and scale production as needed.

- Regulatory Expertise: Partnering with an ISO certified manufacturer guarantees a strong understanding of regulatory requirements, such as ISO certifications and FDA regulations.

- Innovation-Driven Mindset: You want a manufacturer who shares your passiont for innovation. This collaboration can lead to breakthroughs that set your medical devices apart.

- Global Reach: Partnering with a company that offers contract electronics manufacturing services across borders, like in the U.S., Canada, the United Kingdom, and Mexico, opens up new markets and opportunities for your product.

Accelerate Medical Innovation with Expert Electronics Manufacturing from MFG One

In the medical field, innovation relies heavily on the quality and precision of the electronics inside each device. Contract electronics manufacturing services play a vital role in turning cutting-edge ideas into reliable, high-performing medical products.

Partnering with an electronics prototype company, like MFG One, gives you access to technical expertise, regulatory knowledge, and efficient production capabilities-helping you bring your medical devices to market faster. Whether you’re located in the U.S., Canada, the United Kingdom, or Mexico, MFG One helps you stay ahead in the rapidly evolving medical field.

Ready to bring your medical device to market? Contact us today to learn how we can help you accelerate your innovation and production timelines with our contract electronics manufacturing services!