Electronic Prototyping Manufacturing

Electronic prototyping manufacturing converts your digital designs into physical, testable products. MFG One provides this service end-to-end, covering design review, quick builds, and a clean handoff to production. This process helps you save time and costs, while maintaining quality and market standards.

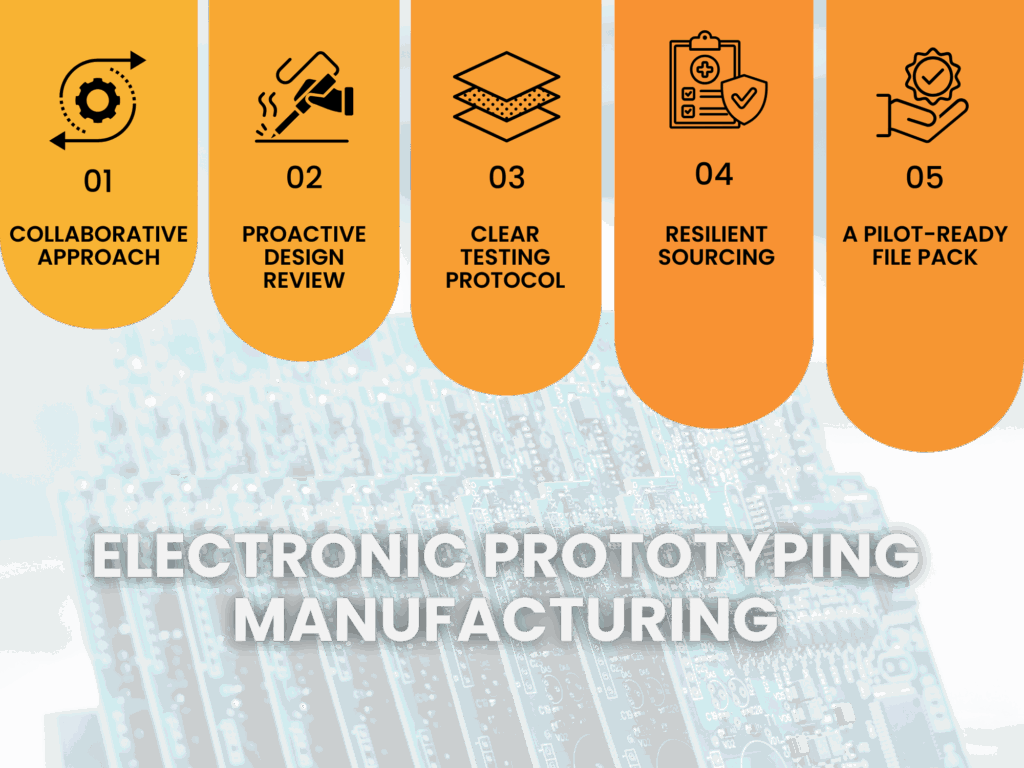

Advantages of Our Electronic Prototyping Manufacturing

When you partner with us for prototype development services, you get concrete, actual results that speed up your product’s time-to-market. We provide early-stage units, predictable turnarounds, and a complete reusable file set.

- Collaborative Approach: By working closely with your team, we focus on your priorities and create results that support your vision and unique needs.

- Proactive Design Review: Before securing materials, we review your design for manufacturability to catch and resolve potential issues early.

- Clear Testing Protocol: Every unit is validated against a clear test plan with objective pass/fail checks for stable performance data.

- Resilient Sourcing: We create a parts plan through our network of vetted suppliers to protect your production from supply chain disruptions.

- A Pilot-Ready File Pack: You receive a complete package with drawings, build notes, and test steps, making the transition to the next phase easier.

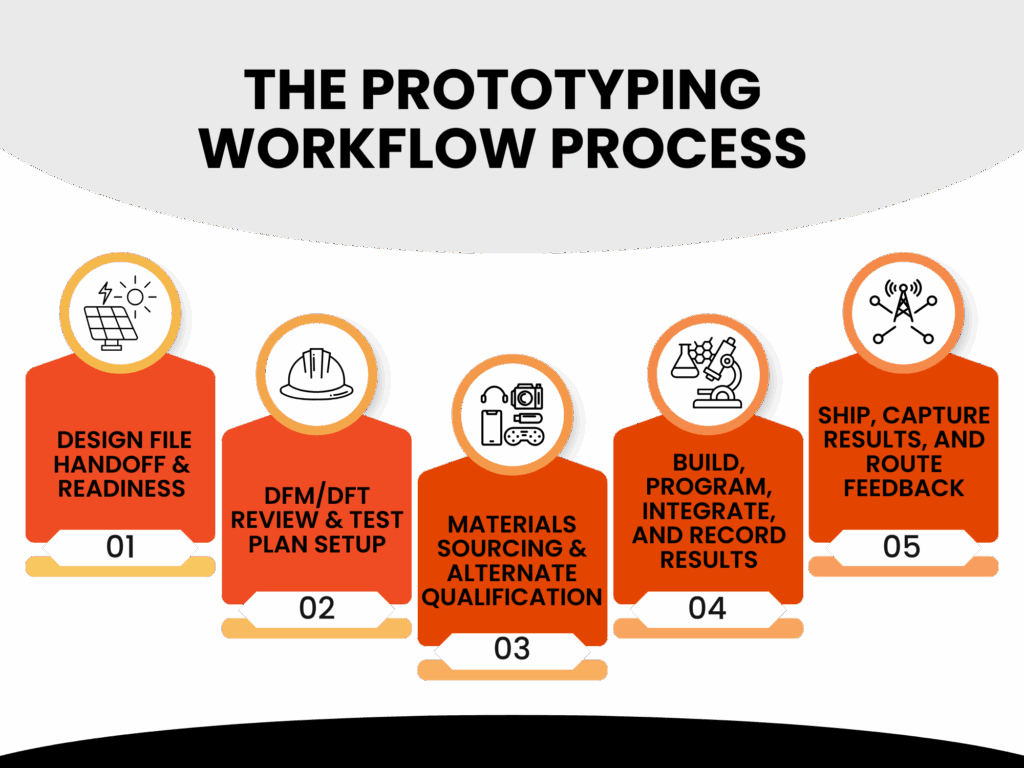

The Prototyping Workflow Process

The most successful electronic prototyping manufacturing runs on a single, visible workflow. This allows activities to move in parallel while critical verification steps remain intact, keeping momentum from the first design to final production. To keep this process steady, each phase must connect seamlessly to the next.

A successful prototype starts with a complete set of instructions. In this initial phase, we confirm all necessary files, including CAD models, schematics, firmware, and test points, making sure your product design is fully ready before the review process begins.

Our electronic design and manufacturing services team conducts a thorough Design for Manufacturability (DFM) and Design for Testability (DFT) review. This step identifies ways to make your product easier and more cost-effective to build and test.

We approve alternate components, identify sources from our network of suppliers, and precisely time our material purchases to the prototype cadence. This stage of electronic prototyping manufacturing keeps all parts qualified and ready the moment the build is scheduled to start.

As experienced box build assembly manufacturers, our team assembles boards, loads firmware, and integrates all components into early-stage builds. Our custom manufacturing and engineering capabilities allow us to handle unique requirements while capturing detailed, production-level results for full traceability.

The process doesn’t end when the units ship. We deliver the prototypes with all documentation tied directly to the build record. We then route key first-pass yield data and relay codes back to your engineering team, creating a tight feedback loop for rapid refinement.

Integrated Transition from Prototype to Pilot

After your prototype is validated, we carry the same engineering files, tooling, and test steps directly into the pilot phase. Because our box build electronic contract manufacturing process is managed in-house, we align PCBA fabrication, enclosure work, cabling, and system tests on a single, efficient schedule. This full-service workflow means that the valuable work done during prototyping directly accelerates your path to manufacturability.

After your prototype is validated, we carry the same engineering files, tooling, and test steps directly into the pilot phase. Because our box build electronic contract manufacturing process is managed in-house, we align PCBA fabrication, enclosure work, cabling, and system tests on a single, efficient schedule. This full-service workflow means that the valuable work done during prototyping directly accelerates your path to manufacturability.

Supporting Quality, Traceability, and Industry-Specific Builds

Our electronic prototyping manufacturing process adheres to the same strict quality controls used in full-scale production. Traceability, performance checks, and clear records are built in from the very first prototype, so your pilot runs start on solid ground. We provide ISO 13485–aligned procedures, serialized tracking, and audit‑ready documentation to meet the demands of even the most regulated markets.

Industries We Support

Our clear, repeatable process as a box build electronic contract manufacturer is adaptable to a wide range of product types and industries, including but not limited to:

Customer Frequently Asked Questions

Manufacturing involves many details, and it’s natural to have questions along the way. That’s why we’ve compiled answers to some of the most common questions we receive from our customers at MFG One.

Prototyping focuses on validation, testing, and refinement in small quantities. The goal is to prove a design works. Production builds are optimized for efficiency, cost-effectiveness, and repeatability at a large scale.

A complete electronic prototyping manufacturing package should include your Bill of Materials (BOM), CAD files, schematics, any firmware, and a clear description of your functional testing requirements.

Yes. Identifying and fixing design flaws and manufacturing issues during the low-volume prototype stage is far less expensive than correcting them once you are in full production.

We handle the entire system. Our electronic product engineering services are centered on "box builds," meaning we assemble the PCBA, integrate it into the enclosure, complete all wiring, and perform system-level functional tests.

Get a Production-Ready Prototype with MFG One

From concept to a complete, tested unit, our electronic prototyping manufacturing service connects your design directly to the early-stage production phase. We deliver complete units, including the PCB, enclosure, and cabling, and complete documentation.

As a contract manufacturer in the USA, we are proud to serve partners across the United States, Canada, the United Kingdom, and Mexico. Request a quote today to schedule your prototyping service.