Box Build Engineering and Prototype Development Services

MFG One’s engineering and prototype development services are designed to enhance manufacturability so that your products meet both quality standards and market demands.

Improving Manufacturability From Prototype to Production

Our engineering and prototype development services are designed to enhance manufacturability so that your products meet both quality standards and market demands.

- Full box build solutions from design to assembly.

- Proficient in 3D printing, CNC machining, and PCB reverse engineering services.

- Adherence to industry standards for product development.

- Streamlined processes with clear communication and efficiency.

Engineering and Prototyping Support for Complex Box Builds

From early-stage design through production-ready builds, we provide full-scope engineering and prototyping services that make complex product development faster, smarter, and more manufacturable.

As an electronic contract manufacturer, we combine in-house expertise with trusted partnerships to offer strong cross-functional capabilities in mechanical, electronic, and digital systems, backed by a deep new product introduction (NPI) expertise. Our diverse background enables us to support the full lifecycle of your product.

Our mechanical engineering team delivers custom solutions across industries, with a focus on design for manufacturability and performance. Our custom manufacturing and engineering solutions include mechanical design, modeling, and rapid prototyping.

Applications We Support

- Custom Mechanical Components: Mechanical parts engineered for box build assemblies to improve overall system efficiency and performance.

- Precision-Engineered Parts: High-quality components developed for aerospace applications, ensuring safety and reliability in critical environments.

- Human Factors Engineering (HFE): Bridging the gap between human capabilities and technological systems to optimize user experience and performance.

- Robust Mechanical Systems: Durable systems engineered for assemblies, built to meet rigorous industry standards for performance and safety.

- Innovative Mechanical Designs: Creative solutions for consumer products that prioritize usability and market appeal.

As a leading contract manufacturer, we support the full scope of electronic development including PCB design, layout optimization, and prototyping for embedded and connected technologies, all the way through to complete product build. Once components are manufactured by our trusted vendors, we bring them back in-house for final assembly.

Applications We Support

- Custom PCB Design and Fabrication: Personalized solutions for IoT devices to meet specific functionality and performance requirements.

- Electronic Prototyping: Rapid development of prototypes for smart home systems to validate concepts and functionality.

- High-Reliability Electronic Components: Specialized components designed for medical devices for enhanced safety and compliance with industry standards.

- Advanced Circuit Design: Fresh designs for telecommunications equipment that enhance connectivity and performance.

Our approach to prototype development services focuses on optimizing products for performance, cost-efficiency, and seamless manufacturability. By applying global best practices early in development, we help reduce complexity, speed up production, and improve overall product quality.

Our Applications & Methodologies

- VAVE (Value Analysis / Value Engineering): Improving function while reducing unnecessary costs.

- DFMA (Design for Manufacturing and Assembly): Simplifying product designs for efficient, scalable assembly.

- DFX (Design for Excellence): Incorporating quality and sustainability into early design stages.

- Lean Manufacturing: Minimizing waste and maximizing efficiency throughout the product lifecycle.

We offer end-to-end electronic prototype manufacturing that spans every stage of the product development cycle. Whether you’re iterating on early concepts or preparing for production, our integrated approach supports speed, precision, and manufacturability.

Applications We Support

- Rapid Prototyping: Fast-track development using 3D printing and CNC machining.

- Mechanical Testing: Evaluate structural strength, function, and durability.

- Electronic Prototyping: Build and test functional PCBs and embedded systems.

- Digital Prototyping: Develop interactive UI/UX models for early user validation.

- Material Analysis: Select optimal materials for function, cost, and scalability.

Phases of Box Build Assembly Manufacturing

Experience seamless contract manufacturing with a rigorous process designed for maximum efficiency and quality. As turnkey box build assembly manufacturers, we help your products get to market faster by expediting design to delivery stages and assisting you in adhering to strict compliance standards.

We start by exploring initial ideas, assess feasibility, and define key features. This step establishes a strong foundation for the development process.

We leverage advanced CAD tools to convert concepts into detailed, production-ready digital models. Our prototype development services prioritize precise visualization and refinement in the design stage before moving to prototyping.

As part of our prototype development services, we create and test early-stage physical and digital prototypes to evaluate functionality, design, and usability. Feedback from this stage drives improvements for the next steps.

We apply DFMA, VAVE, DFT, DFX, and Lean principles to test and validate your product. These methodologies focus on manufacturability, cost reduction, and quality optimization while addressing potential challenges early.

Our box build assembly services streamline the transition to full-scale production by managing component sourcing and bringing everything together for in-house assembly.

From packaging and shipping to lifecycle management and product support services, we manage the final stages to facilitate smooth delivery and long-term success in the market.

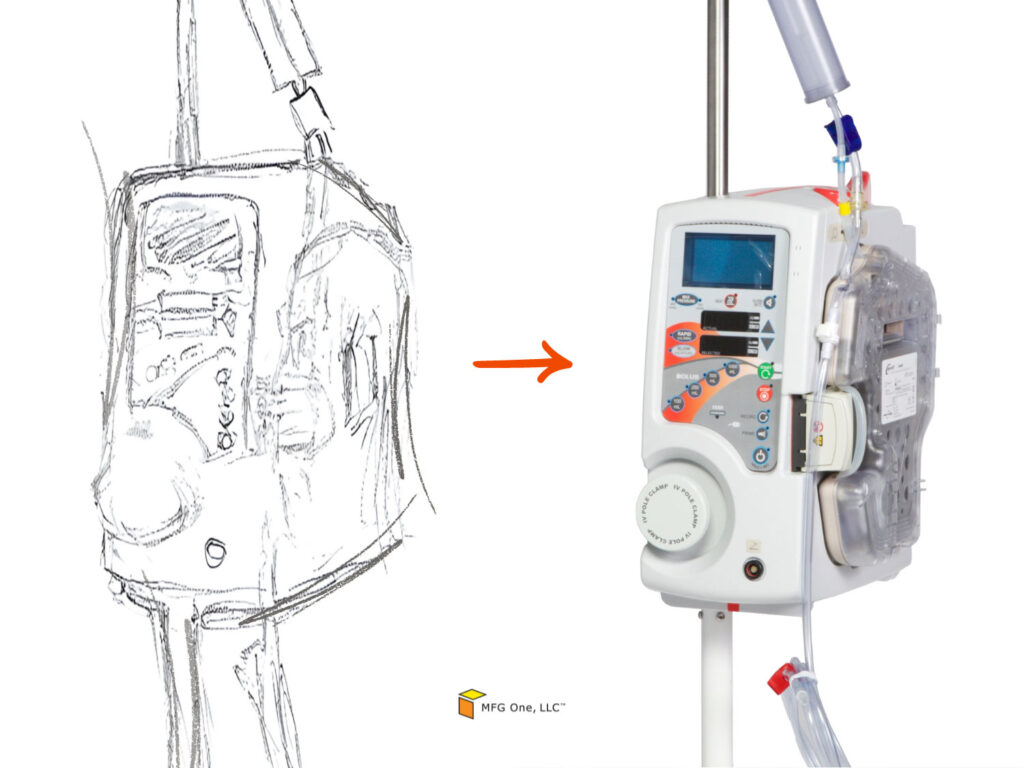

Full Cycle Product Engineering and Design Services

From a product napkin sketch design to existing product improvements, our prototype development services are customized to streamline fast product development, offering a range of expertise:

- Value Engineering

- Cost Analysis

- Biomedical Engineering Services

- 2D–3D Conversion

- Packaging Engineering

- Plastics Engineering

- Product Development

- Prototype Engineering

- Reverse Engineering

- Simulation and Testing

- Software Development Services

- SolidWorks

- Sustaining Engineering

- Human Factors Engineering

- Electrical and Software Engineering

- Electro-Mechanical Engineering

- Quality Engineering

- Engineering Support

- Failure Analysis and Reliability

- FEA (Finite Element Analysis)

- Injection Mold Design

- Mechanical Design Services

- Design and Development

- New Product Introduction (NPI)

- Technical Documentation

- Test Development

Why Choose MFG One for Box Build Product Engineering and Prototyping

Finding the right partner for product engineering and prototyping can be the difference between success and setbacks. At MFG One, we strive to deliver prototype development services that simplify complex manufacturing processes, reduce lead times, and help you bring high-quality products to market faster.

Here’s why we’re the top choice in prototype development services for every OEM manufacturer:

Product Focused

Our team understands the evolving demands of product engineering and prototyping and delivers solutions that are personalized to industry needs and market expectations.

Collaborative Approach

We work with your team to align with goals and deliver results that reflect your vision and meet your unique requirements.

Scalable Solutions

Whether you’re a key industry player or a small innovation-led establishment, our production capabilities are designed to adapt to projects of any size, supporting growth and flexibility at every stage.

Certified Quality Standards

From FDA guidelines in medical devices to ISO and FCC certifications for electronics, we guide you throughout the entire compliance process.

Proximity to Market

Start Your Product Journey with a Leading Turnkey Contract Manufacturer

As a trusted partner serving businesses across the US, UK, Canada, Mexico, and beyond, we offer turnkey prototype development services to meet and exceed the demands of global markets. Our expertise spans design, prototyping, manufacturing, and lifecycle support, verifying every stage of production is handled with precision and efficiency.

Whether you’re developing medical devices, consumer products, or advanced electronics, we provide custom manufacturing services to streamline your journey from concept to commercialization.

Contact us for a free quote on prototype development services.