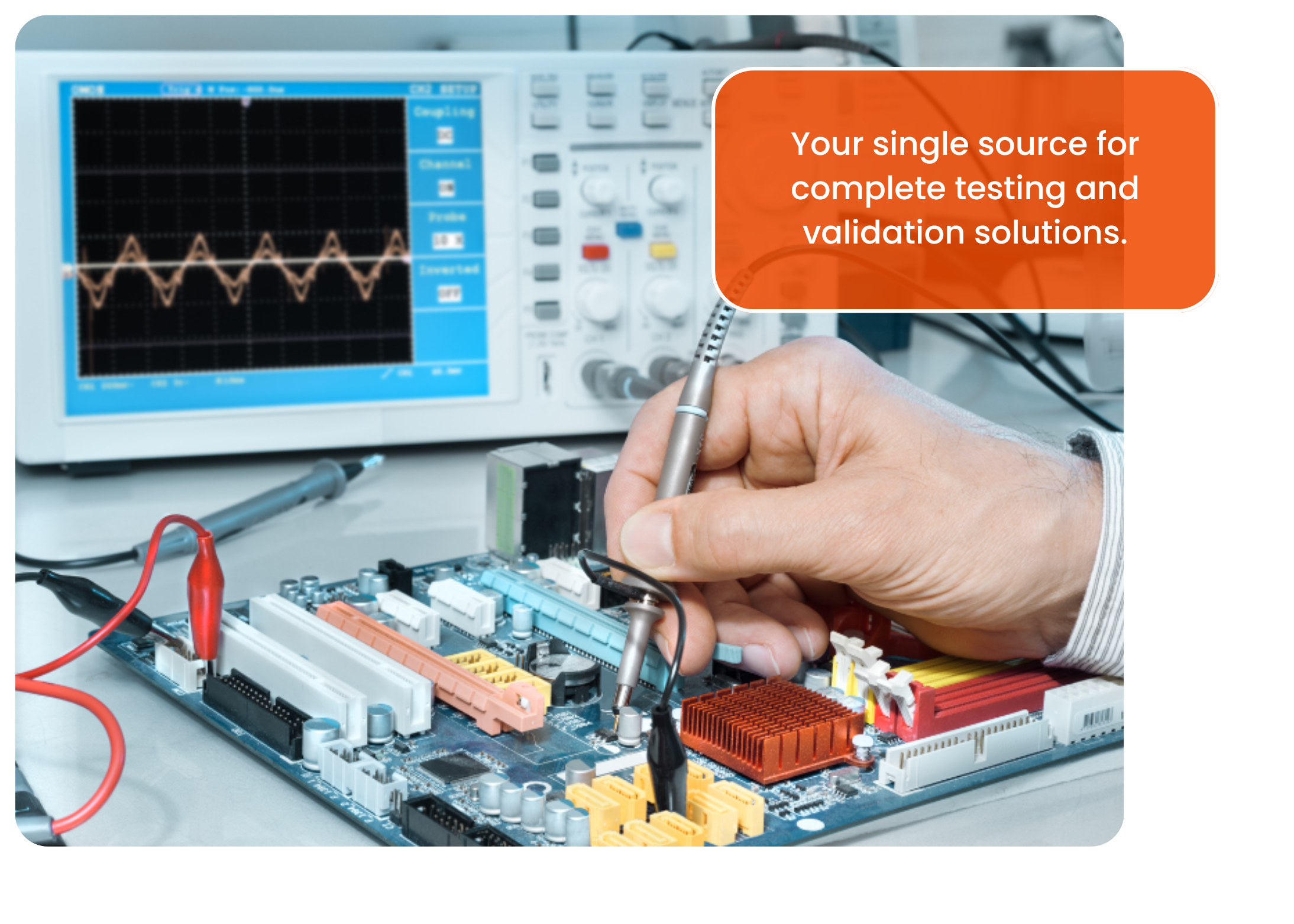

Turnkey Testing and Validation Services

At MFG One, we offer rigorous testing and validation services for regulated industries to give you peace of mind and a competitive advantage.

Full-Cycle Testing and Validation for Box Builds

Thorough product testing can save you from costly errors and inconvenient downtime. We adhere to the highest standards of performance, safety, and compliance. Our full-spectrum testing covers every stage, from early prototypes to final product launches.

- Full-spectrum testing and validation services from early prototypes to final product launch.

- Proven validation processes to confirm performance, safety, and reliability.

- Expertise in quality and compliance standards for regulated industries.

- Hands-on project management to streamline testing and documentation.

- Legal team support for FDA submissions and regulatory compliance.

Integrated Testing and Validation Services for Box Build Product Compliance

MFG One is a turnkey contract manufacturer that offers thorough testing and validation services to help your box-build products meet top performance and compliance standards. Our legal and regulatory affairs team offers hands-on guidance through FDA submissions, including 510(k) and pre-market approval (PMA) pathways. With almost a decade of continuous FDA-compliant operations and a 100% clean audit record with zero defects, we make your product fully prepared for market entry.

As part of our custom manufacturing services, we offer rigorous testing methods to evaluate durability, resilience, and functionality across various conditions, giving you confidence in your product’s readiness for the market.

Vibration Testing

Simulates vibrations during transportation and operation to assess product durability.

Mechanical Shock Testing

Evaluates product resilience under sudden impacts or drops.

Drop Testing

Tests product strength and functionality after free-fall scenarios.

Mechanical Life Testing

Measures the lifespan of moving components under repeated use.

Force, Displacement, and Torque Testing

Analyzes mechanical properties like force exertion, movement, and rotational strength.

Environmental Testing

Examines product performance under varying temperature, humidity, and other environmental conditions.

Measurements and Visual Inspection

Conducts precise measurements and visual assessments to detect defects or inconsistencies.

Continuity Testing

Verifies the uninterrupted electrical path within your products to confirm consistent performance and identify faults like breaks or poor connections.

As a turnkey contract manufacturing provider, we understand the importance of thorough validation in bringing high-quality products to market. Our validation services make every aspect of your product comply with design specifications and functional requirements throughout:

Verification/Validation of Final Unit

Confirms the final product meets design specifications and functional requirements.

Verification/Validation of Software

Tests software for functionality, compatibility, and operational accuracy.

Packaging Design/Validation

Assesses packaging for durability, protection, and compliance with industry standards.

Risk Assessment

Identifies potential risks in design or processes to mitigate issues before production.

Design Failure Mode and Effects Analysis (DFMEA)

Analyzes design weaknesses to prevent failures during product usage.

Process Failure Mode and Effects Analysis (PFMEA)

Evaluates manufacturing processes to reduce defects and improve efficiency.

Supporting Testing and Validation Services in Box Build Applications

At MFG One, we provide a range of testing and validation services tailored for box-build applications, making sure that every product meets necessary performance and compliance standards throughout its lifecycle.

Functional Testing at MFG One

Our functional testing focuses on assessing how software applications perform under different conditions and how intuitive they are for users. As a turnkey electronic manufacturer, we specialize in testing critical aspects such as:

- Performance testing for software applications

- Usability testing for user interface optimization

- Compatibility testing for cross-platform functionality

- Security testing for vulnerability assessment

Complete Physical Product Validation

Physical product validation evaluates physical products’ structural integrity and environmental durability. MFG One provides targeted testing services to assess long-term performance, safety, and resilience under real-world conditions.

- Structural testing for durability and strength

- Environmental testing for temperature and humidity resistance

- Reliability testing for long-term performance

- Safety testing for compliance with industry standards

Full-Service Software Validation For Your Products

Software product validation focuses on optimizing user experience and confirming market readiness through data-driven insights. With our integrated custom manufacturing through our vetted partnerships and engineering process, we develop your products by analyzing user feedback, prototyping designs, and leveraging analytics for continuous improvement.

- Market validation through customer feedback and surveys

- Rapid prototyping and reverse engineering services for iterative design improvements

- Analytics-driven insights for product refinement

Turnkey Testing and Validation Services

We support every stage of your product engineering process, from prototype and design to manufacturing and delivery. Our end-to-end testing and validation services solutions are designed to streamline the process of helping your products meet all regulatory standards and requirements.

Test Planning and Engineering

Building custom test protocols and validation plans customized to your product specifications.

Prototyping Support

Testing early-stage builds to amplify designs and identify potential improvements.

Validation Testing

Verifying product performance, functionality, and compliance with industry standards.

Manufacturing Support

Aligning testing outcomes with scalable production processes for efficient rollout.

Supply Chain Management

Coordinating sourcing, quality checks, and inventory management for a smooth product launch.

Precision Testing for Products That Stand Out

Our testing and validation services are geared towards enhancing every aspect of your product, helping you deliver exceptional quality and performance through these advanced methods:

Simulating long-term usage conditions to assess product durability and performance over time, helping identify potential failures before they occur in real-world scenarios.

Verifying the functionality and consistency of products under various stress conditions. This testing helps confirm that products can withstand demanding environments without compromising quality.

Evaluating how users interact with your product to confirm it is intuitive and user-friendly. Gathering feedback during this phase allows for adjustments that enhance customer satisfaction.

Collecting real customer feedback to inform product improvements and adjustments helps align your offerings with market needs and preferences, fostering greater acceptance.

As a turnkey contract manufacturer, we check that products meet all necessary regulatory and industry standards. This testing is crucial for minimizing risks and verifying that your products are safe for market introduction.

Specialized Validation and Compliance Support

- GMP, cGMP, GLP, GAMP

- IQ/OQ/PQ

- Calibration Management

- FDA 21 CFR Part 820 Electronic Signatures, Electronic Records Consulting

- Computer System Validation

- Design Specification

- Equipment Validation

- Facility Qualification

- FAT & Commissioning

- Final Validation Reports

- Functional Specification

- Process Validation

- Requirements Analysis

- Risk Assessment

- Site acceptance Tests (SAT)

- Software Requirements Specifications (URS)

- Standard Operating Procedures SOPs

- System Validation

- Traceability Matrices

- User Requirements Specifications (URS)

- Validation Gap Analysis

- Validation Master Plan Development

- Validation Program Management

- Vendor Qualification

Partner with a Leading Box Build Contract Manufacturer For Market-Ready Products

Rigorous testing and product validation are critical for identifying flaws, improving functionality, and making sure your products are ready for the challenges of real-world use. By outsourcing these processes, you can enhance productivity and maintain cost control while verifying your products meet high standards.

Our testing and validation services are designed to safeguard your investment, help you deliver consistent quality, and build trust with your customers. As a leading contract manufacturer in the USA, we proudly support businesses not only nationally but internationally including the UK, Mexico, Canada, and beyond.

Contact us to discuss your product testing and validation service needs.