This guide breaks down how a full turnkey strategy for custom electronic product design and development transforms your idea into a market-ready product in less time.

Table of Contents

5 Stages of Custom Electronic Product Design and Development to Shorten Time-to-Market

Getting an electronic product out quickly is one of the easiest ways to get ahead in the market. For OEMs, the most effective strategy to gain this competitive edge is a unified approach to custom electronic product design and development. This integrated process builds a direct bridge between a concept and the consumers, eliminating friction, rework, and fragmented processes that happen during a typical product launch.

This guide breaks down how a full turnkey strategy for custom electronic product design and development transforms your idea into a market-ready product in less time.

An engineer finalizing a 3D CAD model, illustrating the design and engineering stage of product development. This critical phase translates a validated concept into a detailed technical blueprint, allowing teams to finalize mechanical designs, component layouts, and ergonomic details before prototyping begins.

What are the 5 Stages of Custom Electronic Product Design and Development?

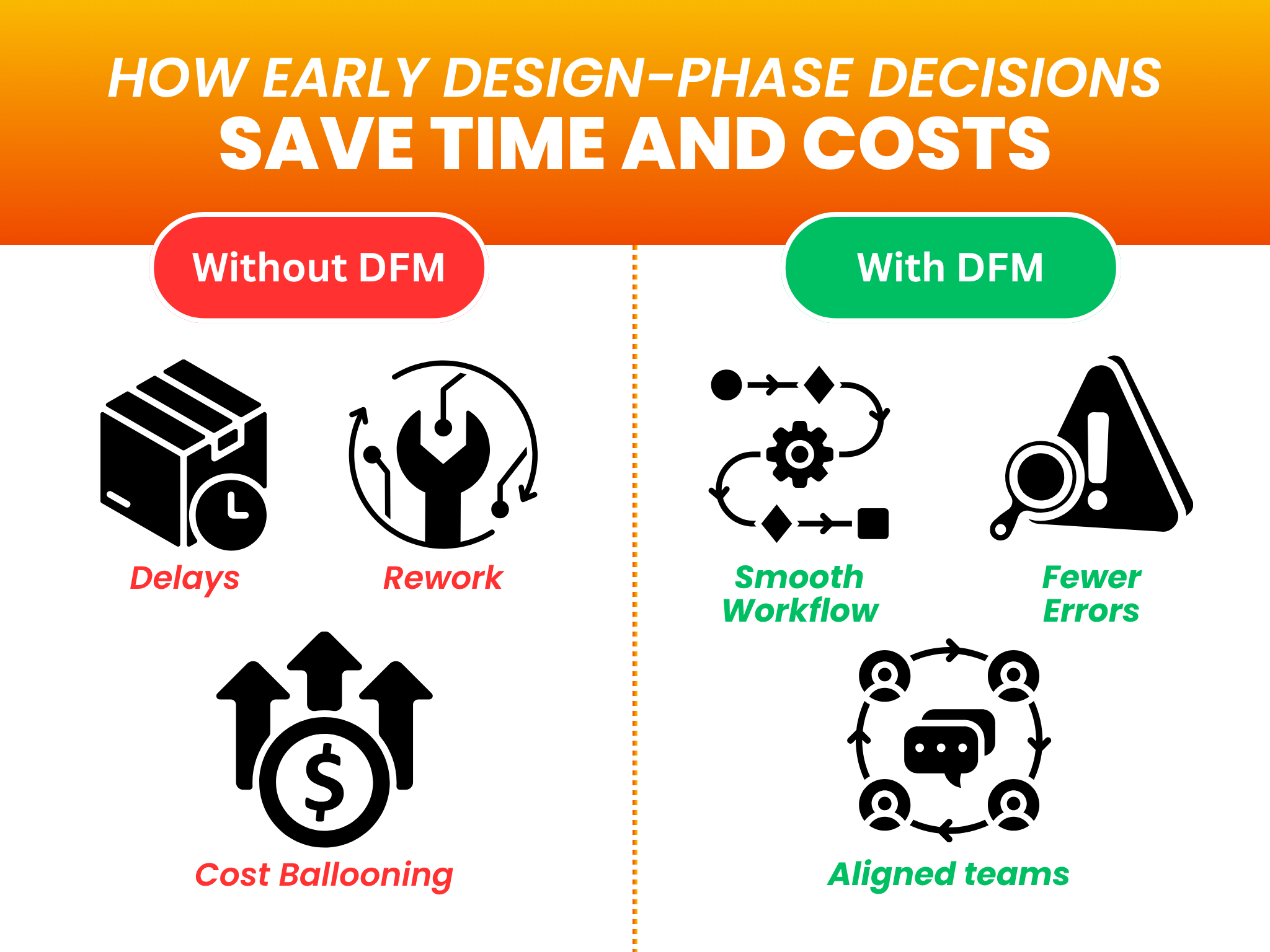

The biggest time savings in product development don’t come from rushing the final stages, but from making more strategic decisions at the very beginning. This is the core principle of Design for Manufacturability (DFM), which integrates manufacturing expertise into the early design phase.

Thinking about how to build a product at scale from the start allows you to prevent costly redesigns, streamline material sourcing, and eliminate production bottlenecks. This approach, guided by professional design and engineering services, is the foundation of a faster launch and a core part of any successful product development strategy. It’s the difference between finding problems on the assembly line and preventing them in the design lab.

What Turns A Product Concept Into A Manufacturable Blueprint?

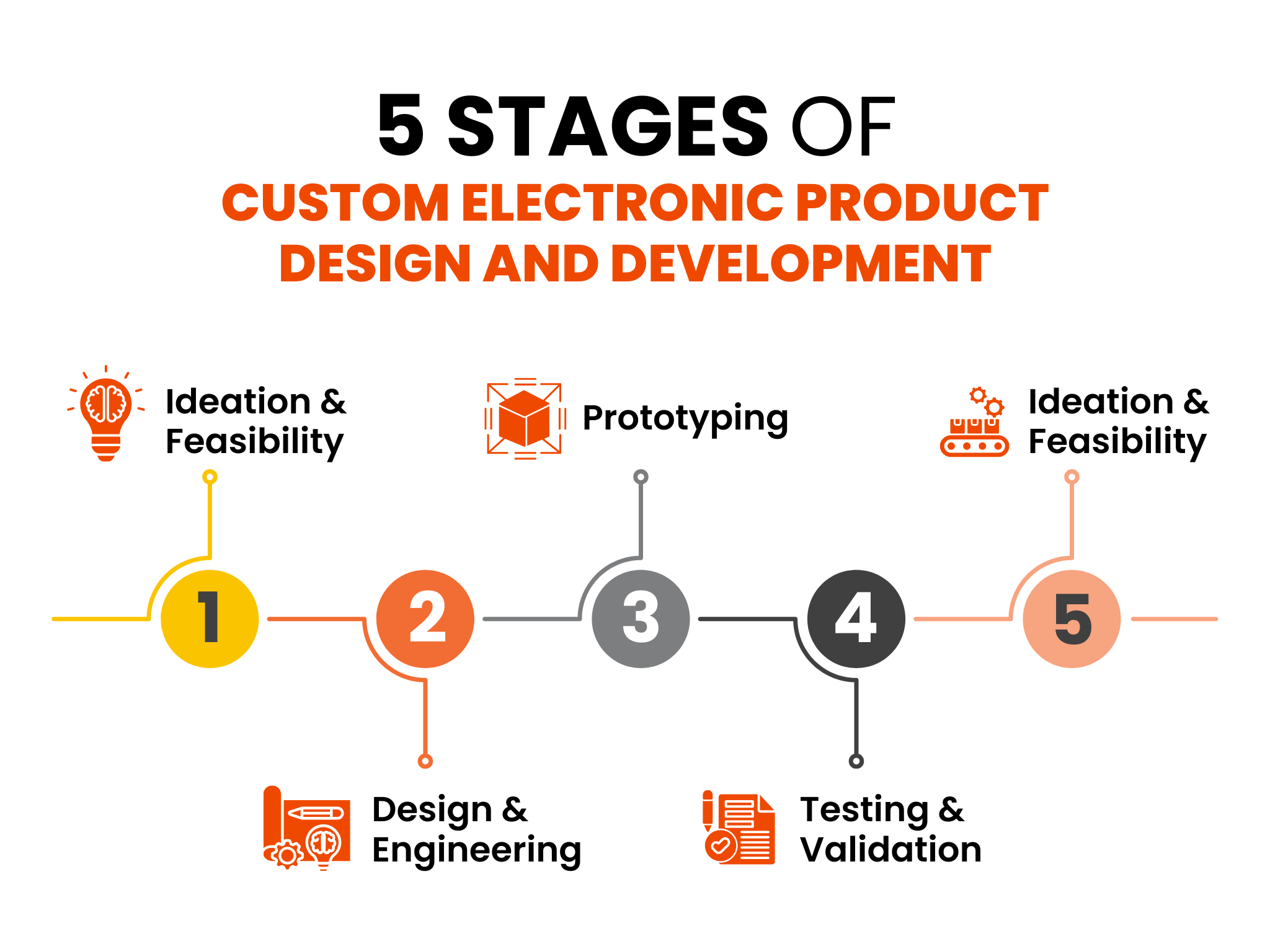

Before someone orders a component or builds a single prototype, they must translate a raw idea into a viable, structured plan that includes what happens after manufacturing the product. This process, often called the custom electronic product design and development lifecycle, is designed to de-risk the project at every step.

It moves a concept from a simple “what if” to a detailed blueprint with defined requirements, a clear bill of materials, and a validated business model. This initial phase of product design and engineering creates a “single source of truth” that all teams, from engineering to logistics, can follow. It secures alignment before the costly development work begins.

What are the 5 Stages of Custom Electronic Product Design and Development?

While the operational benefits clearly illustrate a more streamlined workflow, explicitly considering the project management aspect reinforces the value. A turnkey contract from a box build assembly manufacturer simplifies project management by consolidating responsibility. It represents a single agreement covering the entire scope of production.

In contrast, a non-turnkey approach causes managing multiple distinct contracts, relationships, and lines of communication. The turnkey model provides a clear, unified structure, making project tracking, issue resolution, and overall management significantly more straightforward, directly reflecting the operational benefits of hiring a turnkey production manufacturer.

How Do I Get From a Working Prototype to a Successful Product?

A working prototype is a major milestone, but it is not the finish line. This is a common hurdle in the custom electronic product design and development process where many projects get stuck. Design for Manufacturability (DFM) and process validation build the bridge from a single, working prototype to thousands of successful products.

This involves optimizing the design for high-volume production, planning for components like custom injection mold tooling for enclosures, and executing pilot runs with ongoing manufacturing support services. This DFM process is a critical part of making sure that the product is not just functional, but also cost-effective and reliable to build at scale.

Why an Integrated Manufacturing Process Speeds Up Development

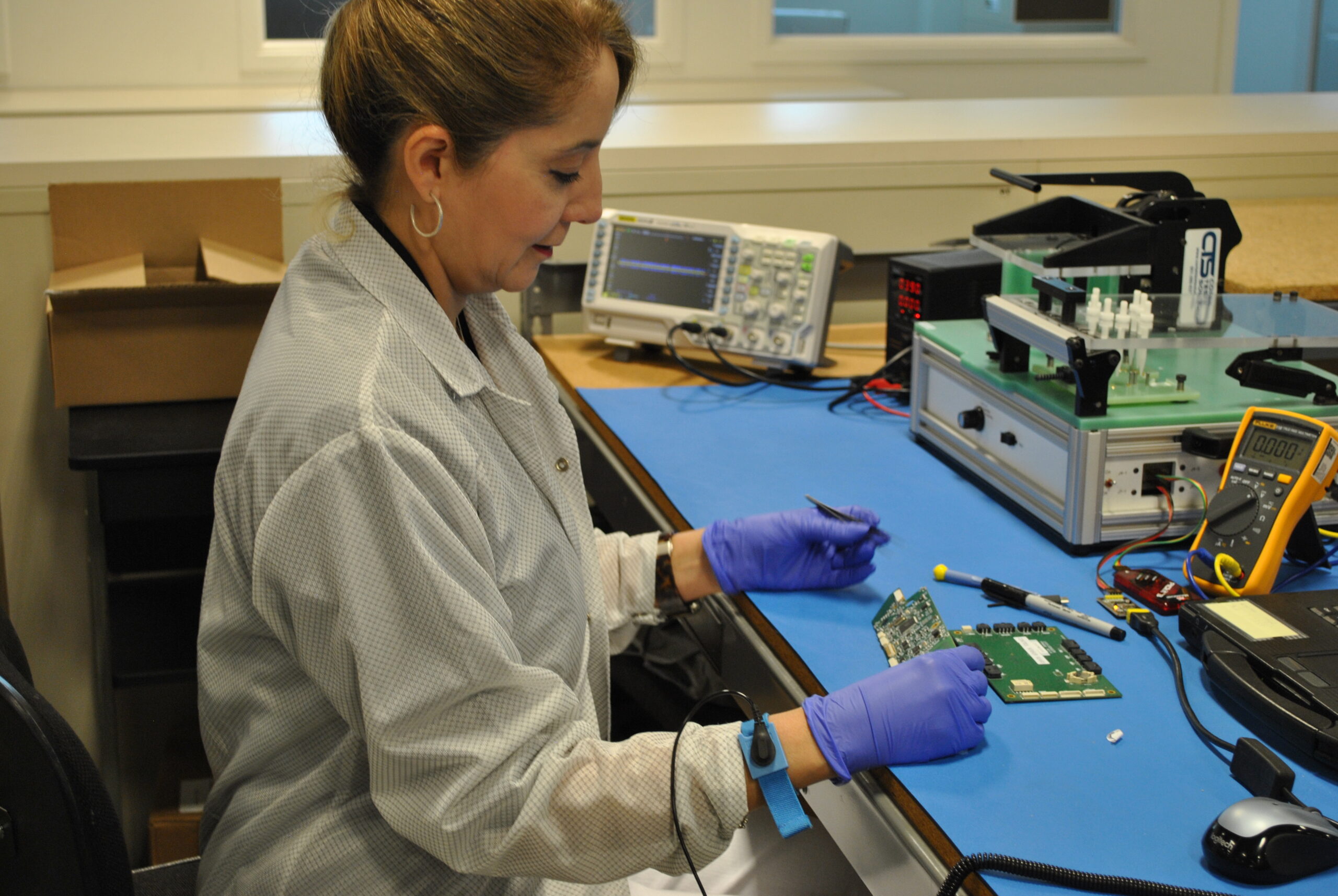

A technician performs detailed diagnostics on a prototype circuit board, a key part of the testing and validation stage. This rigorous, iterative process is essential for verifying that the design meets all functional and performance requirements and for correcting flaws before committing to full-scale manufacturing

While the five stages of product design and development provide a roadmap, true acceleration comes from how they are managed. The greatest sources of delay are the handoffs between separate, uncoordinated teams from a design firm to a contract manufacturer. Each handoff introduces a risk of miscommunication and time-consuming revisions.

A single partner, acting as a unified product development company, eliminates this friction. By overseeing the entire process, from initial design to final assembly, they can make decisions in the design phase that directly benefit manufacturing. This is the specialty of a true box build electronic contract manufacturer, who manages the full custom electronic product design and development strategy, preventing the operational gaps that consume valuable time.

Your Partner for Custom Electronic Product Design and Development

Shortening your time-to-market directly results from a strategic, integrated approach. By planning all manufacturing decisions and eliminating handoff delays with a single partner, you create the most efficient path from concept to customer. This is the core value of an efficient custom electronic product design and development strategy.

MFG One is a box build electronic contract manufacturer whose professional teams provide end-to-end support for clients across the United States, Canada, the United Kingdom, Mexico, and beyond.