Table of Contents

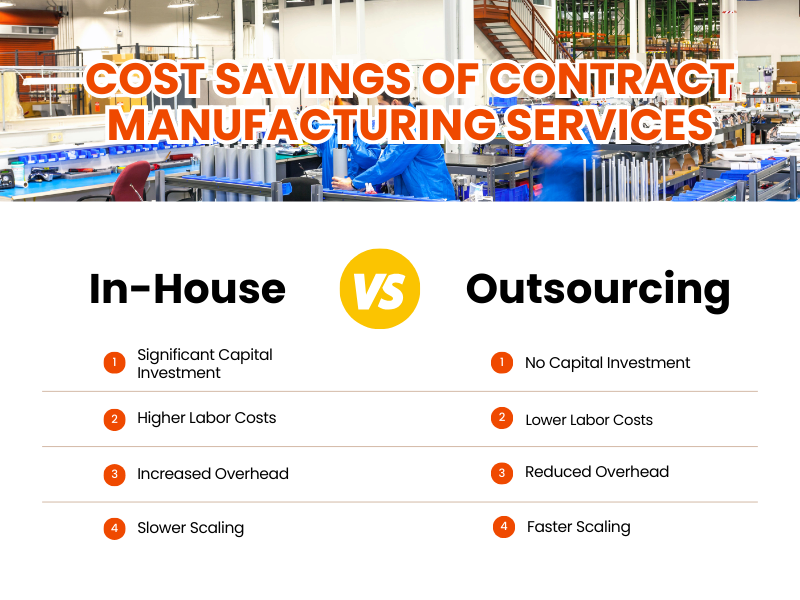

Cost Savings: In-House vs. Outsourcing

- No Capital Investment: Skip the upfront costs of purchasing equipment like injection molding machines or PCB assembly lines.

- Lower Labor Costs: Access skilled professionals without the ongoing expenses of full-time staff.

- Reduced Overhead: Contract manufacturers already have facilities designed for high-volume production, cutting down on overhead costs for you.

- Faster Scaling: Easily ramp up production without the growing pains of building an in-house facility.

Faster Time to Market with Full-Service Support

- Product Design & Development: Collaborating with an electronics prototype company allows you to refine your medical equipment from concept to production-ready.

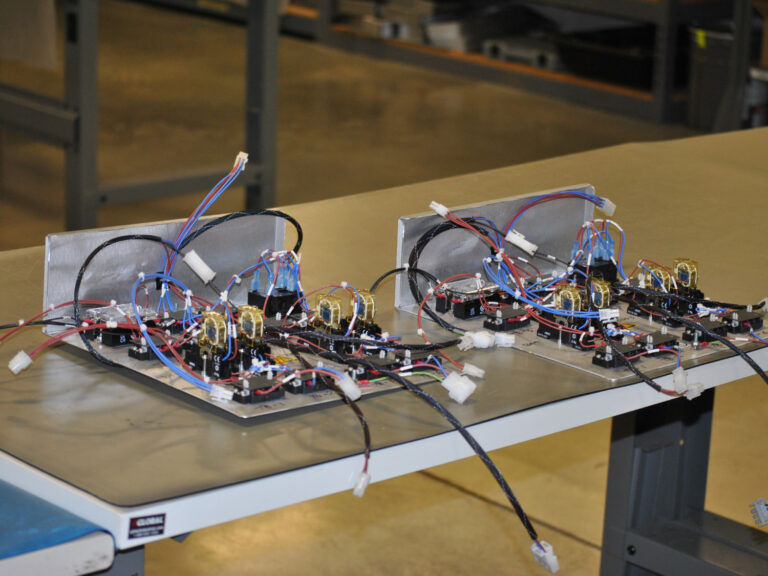

- Prototyping: Rapid prototyping helps you test, adjust, and perfect your device before full-scale manufacturing, reducing the risk of errors in the final product.

- Full-Scale Production: From EMS contract manufacturing to printed circuit board assembly, these companies handle large-scale manufacturing needs seamlessly, maintaining speed and precision.

FDA Compliance & ISO Certification: A Must for Medical Devices

- FDA Compliance: A trusted contract manufacturer is well-versed in the rigorous FDA medical device validation requirements, making sure your product meets the necessary guidelines for a smooth market entry.

- ISO Certification: Partnering with an ISO certified manufacturer guarantees that your product aligns with the highest quality standards, which is essential for both domestic and international markets.

- Verification and Validation Services: These services help streamline the approval process by addressing regulatory challenges early on, reducing potential roadblocks.

This approach not only supports a faster time to market but also reduces the risk of costly delays or rejections due to compliance issues.

Risk Management and Mitigation with Contract Manufacturing Companies for Medical Devices

Key risk management benefits include:

- Expertise in Regulatory Compliance: Experienced manufacturers are well-versed in FDA guidelines and validation requirements, minimizing the chance of costly errors or delays in the approval process.

- Quality Control: By working with a company that offers verification and validation testing, you can be confident that the quality and safety of your medical devices will be upheld, reducing the likelihood of defects and recalls.

- Supply Chain Stability: Outsourcing manufacturing also allows you to leverage a robust supply chain network, minimizing risks related to raw material shortages or production delays.

By partnering with a reliable contract manufacturing electronics company, you’re not just outsourcing manufacturing; you’re gaining a strategic partner that helps you navigate complex risks in a highly regulated industry.

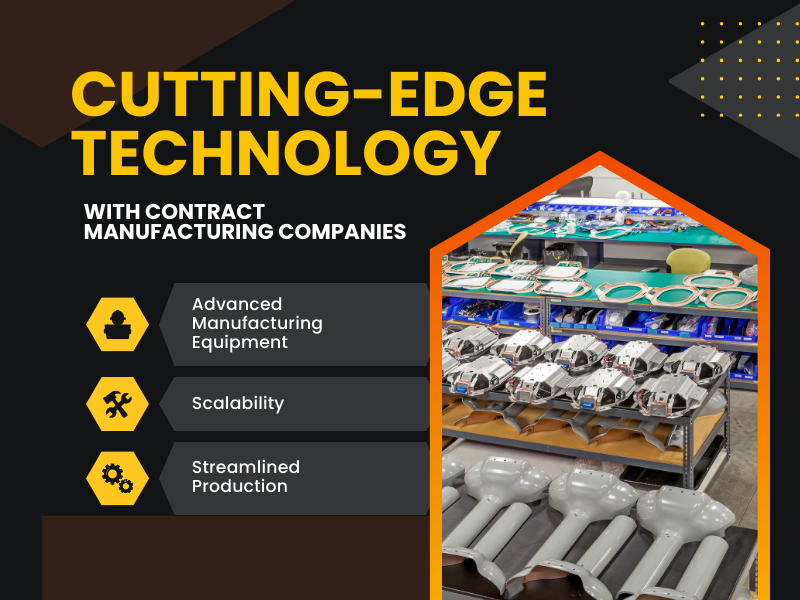

Access to Cutting-Edge Technology Through Contract Manufacturing Companies for Medical Devices

One of the greatest advantages of working with contract manufacturing companies for medical devices is the access to advanced technology and manufacturing processes. These companies invest in state-of-the-art equipment and streamlined systems that allow for efficient, high-quality production of complex medical devices.

Here’s how partnering with contract manufacturers provides access to the latest technology:

- Advanced Manufacturing Equipment: From precision injection molding machines to full-scale production capabilities for printed circuit board assemblies, contract manufacturing companies for medical devices provide the tools needed for intricate and reliable product development.

- Streamlined Production: By leveraging advanced technology, you gain faster production times, higher accuracy, and lower chances of errors or defects during the manufacturing process.

- Scalability: Whether you need a few prototypes or mass production, contract manufacturers have the technology and capacity to scale your production up or down based on market demand.

Choose MFG One for Your Medical Device Manufacturing Needs

Partnering with the right contract manufacturing company for medical devices maintains a smooth, efficient product launch. MFG One offers a full range of services, from initial concept to commercialization, making your journey to the US market faster and more efficient. With expertise in FDA medical device validation, ISO-certified manufacturing, and risk management, we help you navigate every hurdle while maintaining quality and compliance.

Ready to simplify the production process for your medical equipment? Contact MFG One today to explore how our comprehensive contract manufacturing services can help you achieve faster time to market with confidence and precision.