The medical industry thrives on precision. Every piece of equipment and component is a critical puzzle piece in the complex care delivery system. However, finding parts that perfectly fit can be complex, with diverse patient needs and operational challenges. Aftermarket parts manufacturers offer a solution by providing customized components tailored to specific medical requirements, optimizing equipment performance, and enhancing patient care.

From hospitals seeking to streamline workflows to research facilities pushing the boundaries of medical science, the demand for tailored solutions is undeniable. Aftermarket parts manufacturers have risen to meet this challenge, offering diverse customization options that empower medical professionals to optimize their operations and deliver exceptional patient outcomes.

The Rise of Customization and Personalization

There has been a growing emphasis on customization and personalization across various industries in recent years. The medical sector is no exception. As technology advances and patient needs evolve, the demand for tailored solutions has surged. This trend is driven by several factors, including:

- Diverse patient needs: Medical professionals encounter a broader spectrum of patient conditions every year, increasing the need for specialized equipment to address these unique challenges.

- Technological advancements: Breakthroughs in technology enable the development of increasingly precise and personalized medical devices. Customization harnesses these advancements, offering superior patient care and streamlining medical procedures.

- Cost-effectiveness: Custom parts can be a cost-efficient alternative to replacing entire medical systems. By extending the lifespan of existing equipment, customization minimizes the need for frequent, expensive purchases.

- Regulatory compliance: As regulations evolve, medical facilities must adapt their equipment to meet new standards. Customization allows for seamless modifications to meet evolving standards without the disruption and expense of full-scale replacements.

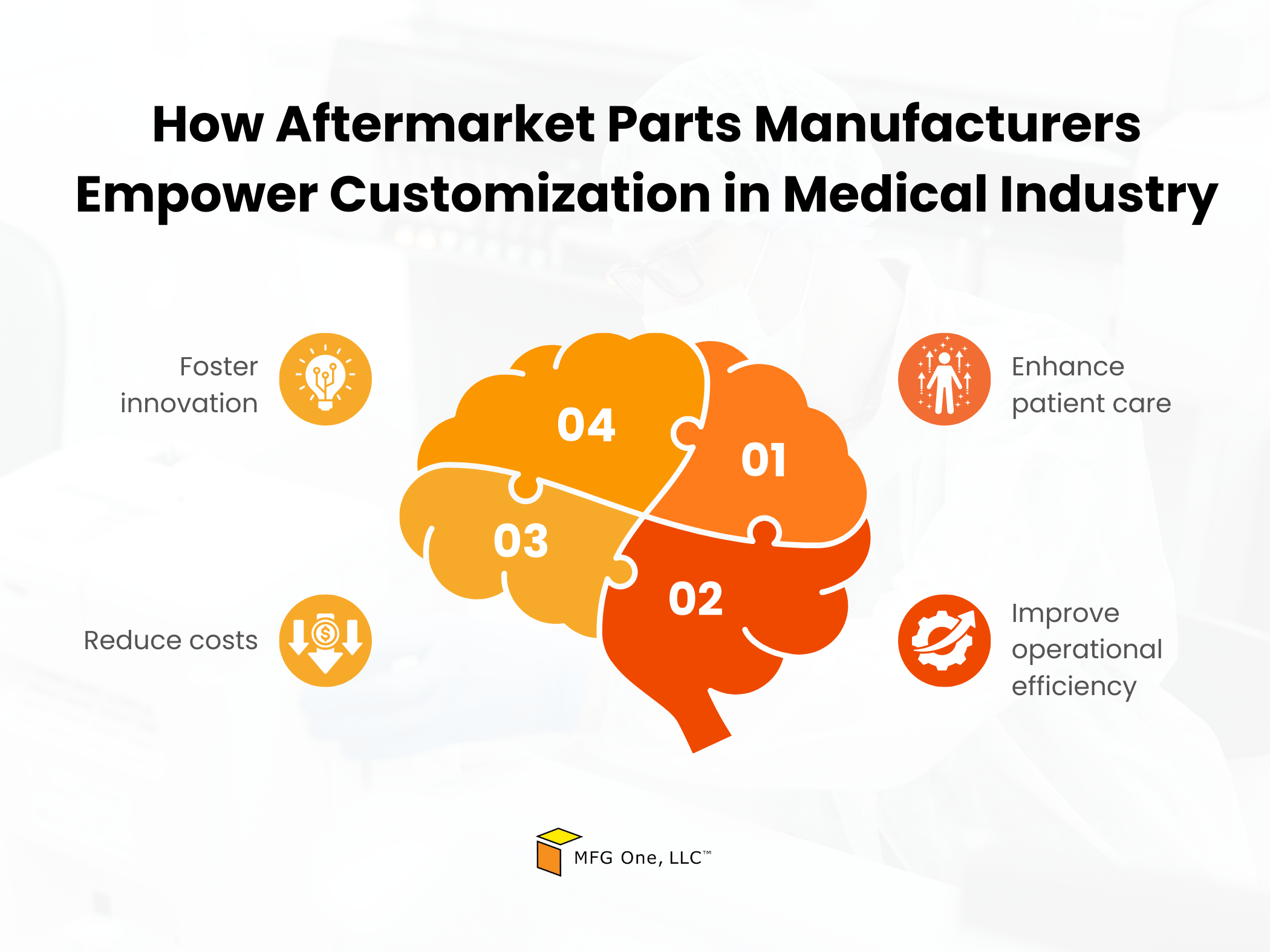

How Aftermarket Parts Manufacturers Empower Customization and Personalization

Full-service contract manufacturers are at the forefront of this customization revolution. These specialized companies offer a variety of services that enable medical facilities to tailor their equipment precisely to their needs, resulting in significant benefits:

- Enhance patient care: Customizing equipment to meet the needs of specific patient populations or conditions can lead to better treatment outcomes and higher patient satisfaction.

- Improve operational efficiency: Customized components can increase productivity and reduce costs by optimizing equipment performance and reducing downtime.

- Reduce costs: Precisely engineered components minimize waste and unnecessary expenses while extending medical equipment’s lifespan.

- Foster innovation: Collaborating with manufacturers allows for developing new and innovative medical solutions, driving advancements in patient care and setting new industry standards.

Types of Customization and Personalization Offered by Aftermarket Parts Manufacturers

Contract manufacturers in the USA offer various customization and personalization options to cater to the diverse needs of the medical industry.

These include:

- Component modifications: Aftermarket parts manufacturers can adjust or adapt existing components to meet unique requirements, ensuring optimal performance in various settings.

- Custom fabrication: When standard solutions fall short, entirely new parts can be designed and manufactured from the ground up.

- Material upgrades: Contract manufacturers can produce components using advanced materials that ensure improved durability, hygiene, or functionality to meet specific demands.

- Integration: These manufacturers can develop parts that allow for the seamless integration of different pieces of equipment, enhancing overall system efficiency.

- Ergonomic improvements: Custom parts can be designed to improve the comfort and usability of medical equipment for patients and healthcare providers.

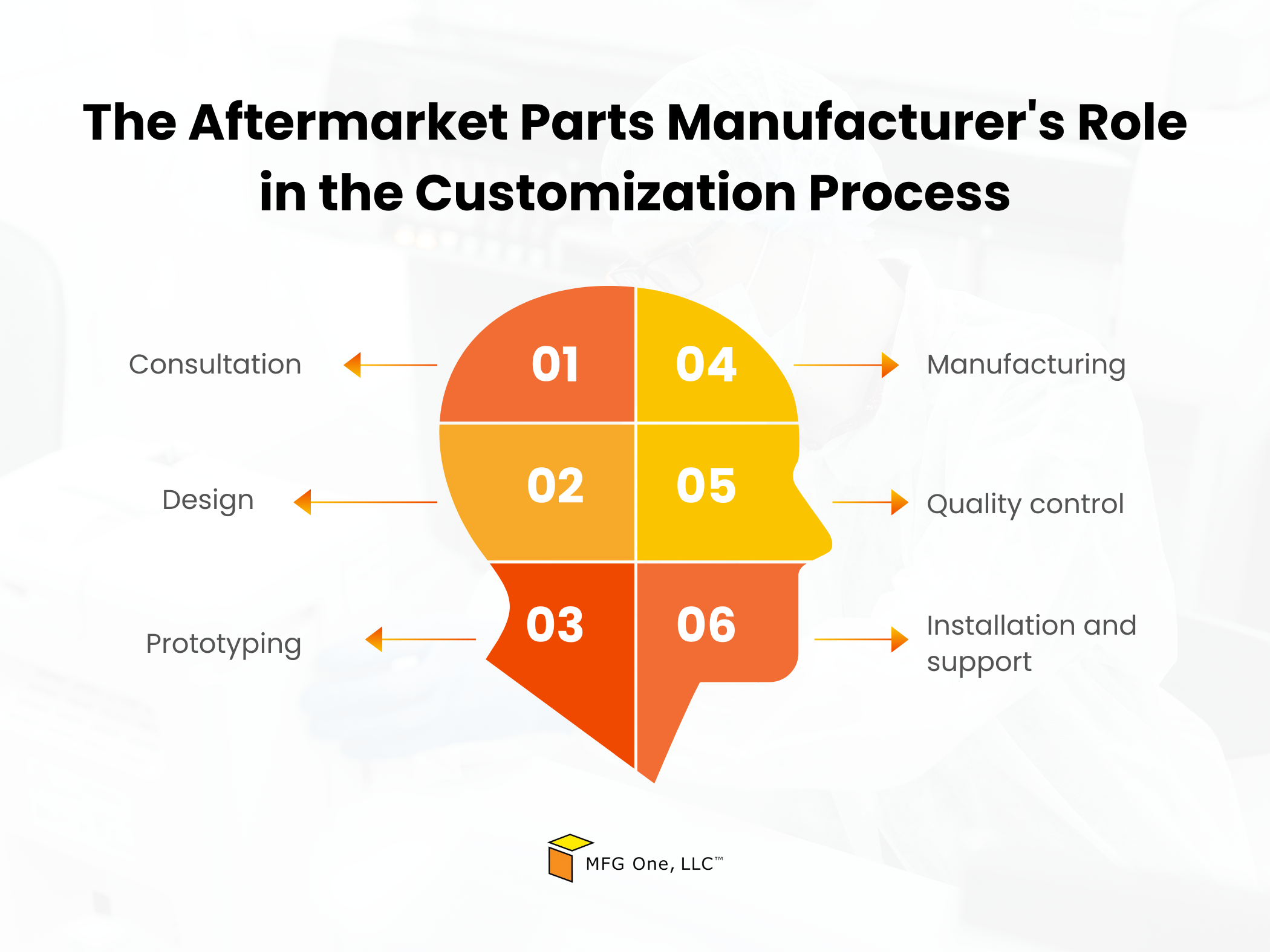

The Aftermarket Parts Manufacturer's Role in the Customization Process

Aftermarket parts manufacturers also play a crucial role in the customization process, where they can offer expertise and support at every stage:

- Consultation: The process starts with a thorough consultation, during which the manufacturer works closely with your medical facility to understand your specific needs and challenges.

- Design:Full-service manufacturers provide comprehensive product design and development solutions, creating detailed designs for custom components that meet your exact requirements.

- Prototyping: Before full-scale production, a prototype is often produced to test the functionality, fit, and performance of the custom part and ensure it meets all necessary standards.

- Manufacturing: Once the design is finalized and approved, the aftermarket parts manufacturer produces the custom components using proven techniques and advanced manufacturing processes.

- Quality control: Rigorous testing and quality assurance processes ensure that all custom parts meet the highest safety, performance, and durability standards.

- Installation and support: Many manufacturers also offer installation services and ongoing support to ensure that the custom solutions continue to meet your facility’s needs over time, adapting as necessary.

Choosing the Right Aftermarket Parts Manufacturer

Selecting the right aftermarket manufacturing partner is a critical step in ensuring the success of any customization project. When evaluating potential partners, consider the following factors:

- Experience in the medical industry: Look for a manufacturer with extensive experience producing medical-grade components. Their familiarity with industry standards and regulations is invaluable.

- Technical capabilities: Ensure the manufacturer has the necessary equipment and expertise to produce the specific parts you require. This includes advanced manufacturing technologies and skilled personnel.

- Quality certifications: Verify that the manufacturer adheres to relevant quality standards and holds appropriate certifications, such as ISO 13485 for medical devices.

- Collaborative approach: Choose an aftermarket parts manufacturer that values partnership and is willing to work closely with your team throughout the customization process. Good communication is essential for successful outcomes.

- Scalability: Consider whether the manufacturer can accommodate your needs as they grow or change. A partner that can scale with your business is invaluable.

- Cost-effectiveness: While quality should be the primary concern, evaluating the manufacturer’s pricing structure is equally important. This ensures their services align with your budget.

- Innovation capabilities: Assess the manufacturer’s ability to innovate and solve complex problems creatively. This can be crucial for addressing unique challenges in medical equipment customization.

- Turnaround time: Evaluate the manufacturer’s ability to deliver custom parts within your required timeframe. Quick turnaround can be critical in the medical field.

- Post-production support: Consider the level of after-sales support offered, including troubleshooting, maintenance, and potential future modifications.

MFG One: Your Partner in Engineering and Design Services

At MFG One, we understand the critical role of customization and personalization in the medical industry. As an aftermarket parts manufacturer, we offer a comprehensive range of contract manufacturing services to help you achieve your goals. Our expertise, advanced manufacturing capabilities, and commitment to quality make us the ideal partner for your customization needs.

Whether you are looking for product development, assembly, or 3PL services, MFG One has the expertise and resources to bring your vision to life. We pride ourselves on our collaborative approach, working closely with our clients throughout the customization process to ensure optimal results.

We provide our services to national and international clients across the USA, the United Kingdom, Canada, and Mexico. Contact MFG One today to discuss your unique needs and discover how our expertise in medical equipment customization can benefit your facility.