Manufacturing can quickly become a costly endeavor when you factor in overhead, floor space, equipment, and labor. On top of that, handling everything in-house isn’t always the most productive or efficient approach. For many manufacturers, certain products that once had high-profit margins may become less profitable over time but still remain vital to the business. This is where outsourcing manufacturing, especially to a contract manufacturer in the USA, can make a significant difference.

Table of Contents

#1. Cost Savings

Outsourcing manufacturing can significantly reduce operational costs, enabling businesses to operate more efficiently and invest in areas that matter most. By working with a contract manufacturer, companies can offer financial advantages that wouldn’t be possible with in-house operations.

- Lower Overhead: Reduce expenses related to facility maintenance, equipment upgrades, and utilities without the need for large capital investments.

- Optimized Labor Costs: Minimize the need for hiring, training, and managing a full in-house manufacturing team.

- Better Resource Use: Reallocate capital to areas like product design and development, marketing, or business expansion.

- Bulk Purchasing Power: Benefit from lower material costs through the contract manufacturers’ ability to buy in bulk.

- Reduced Downtime Costs: Avoid the costs associated with idle equipment or underutilized staff during slow periods, as outsourcing offers flexible production scaling.

Outsourcing manufacturing doesn’t eliminate all costs, but it helps businesses lower expenses significantly while creating opportunities to reinvest in growth and innovation.

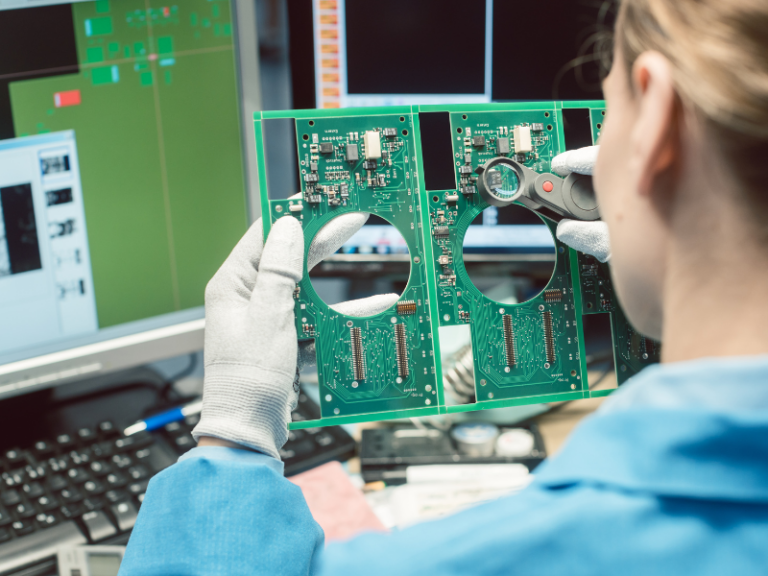

#2. Access to Specialized Expertise

Working with a full-service contract manufacturer opens the door to expertise and advanced technology that may not be available in-house, giving your business a significant edge in the market.

- Technical Expertise: Gain access to professionals with extensive experience in the latest manufacturing best practices, especially those with expertise in industries like medical device manufacturing. Their ability to manage complex processes efficiently reduces the risk of costly errors and provides compliance with industry standards.

- Advanced Facilities and Tools: Benefit from specialized facilities and services, such as injection molding design services or printed circuit board assembly services, and cutting-edge production tools that improve product quality, reduce production time, and streamline operations.

- Customized Strategies: Receive custom solutions that improve product design and optimize production processes, resulting in lower costs, faster turnaround times, and increased product performance.

#3. Focus on Core Competencies When Outsourcing Your Manufacturing

Outsourcing allows your team to concentrate on business-critical tasks while leaving production to experts who specialize in those areas.

- Streamlined Operations: Offload production tasks, including engineering and design services, assembly services, packaging design, and other key areas to a trusted partner. This reduces internal workload and allows your team to focus on high-value activities such as product strategy, business development, and market expansion.

- Prioritization of Innovation: With production handled by experts, your team can devote more time to innovating new products, refining existing designs, and exploring new market opportunities.

- Simplified Processes: Outsourcing manufacturing reduces the need to manage production facilities, supply chains, and inventory systems internally. Relying on a dedicated partner to handle logistics, shipping, and procurement allows you to focus on higher-level tasks, ultimately simplifying the entire process.

#4. Scalability and Flexibility

- Scalable Production: Adjust production volumes up or down based on market demand without investing in new equipment or staff, keeping costs manageable.

- Adaptable Solutions: Seamlessly switch between product lines or projects, enabling faster time-to-market and reducing the complexity of in-house resource management.

- Risk Mitigation: Minimize financial risks by avoiding overcommitting to production capacity. This will allow you to better manage fluctuations in demand and market conditions.

- Faster Response Times: Quickly adapt to customer needs by taking advantage of a contract manufacturer’s aftermarket services, allowing your business to meet demand spikes or shifts without delays.

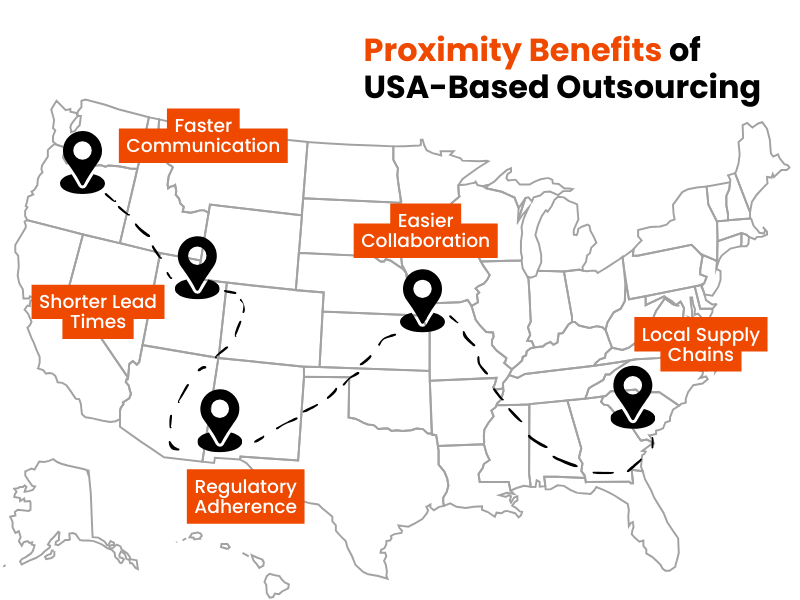

#5. Proximity Benefits of USA-Based Outsourcing

- Faster Communication: Collaborate in real-time with teams in the same time zone, eliminating the delays often caused by time zone differences and offering more efficient decision-making and problem-solving.

- Shorter Lead Times: Reduce shipping delays and avoid complex customs procedures, providing faster delivery times and more predictable timelines. U.S.-based outsourcing also eliminates tariffs when shipping locally, making the overall process more cost-effective.

- Regulatory Adherence: Work with manufacturers who are familiar with U.S. quality and compliance standards, reducing the risk of non-compliance, costly delays, and regulatory issues.

- Easier Collaboration: Proximity enables face-to-face meetings, smoother communication, and quicker feedback loops, leading to more effective problem-solving and project management.

- Local Supply Chains: Leveraging local supply chains reduces dependence on international suppliers, cutting down on lead times, lowering costs, and minimizing disruptions caused by global supply chain issues.