Printed circuit boards (PCBs) are the foundation of modern electronics, acting as the critical link between components and functionality. From smartphones to advanced medical devices, PCBs support the reliability and performance of electronic equipment. For businesses, partnering with a printed circuit board assembly manufacturer goes beyond mere production, it’s about achieving precision, efficiency, and compliance in every board produced.

In this blog, we’ll explore the benefits of working with a PCB assembly manufacturer, what services you can expect, and how their expertise contributes to faster production timelines, cost savings, and high-quality products. Whether you’re in healthcare, automotive, or consumer electronics, understanding the value of a specialized partner can improve your approach to PCB assembly.

Table of Contents

What to Expect from a Printed Circuit Board Assembly Manufacturer

A printed circuit board assembly manufacturer provides the expertise and resources needed to turn your electronic designs into functional and reliable PCBs. Their services often align with electronic product design and development, covering every aspect of production to ensure each board meets stringent quality standards.

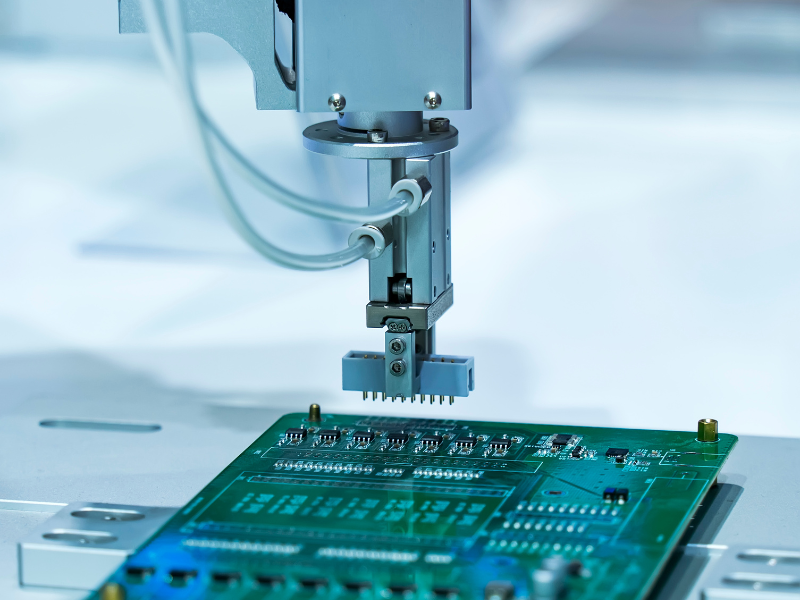

- Assembly and Placement: Using advanced equipment, manufacturers precisely position and secure electronic components onto the PCB, delivering consistent performance and high precision in the final assembly.

- Testing and Quality Control: Manufacturers conduct thorough testing processes, such as Automated Optical Inspection (AOI) and X-ray analysis, to detect any defects or inconsistencies. This approach confirms the boards meet client specifications and operational requirements.

- Customization for Specific Applications: Whether the PCB is for medical equipment or consumer devices, manufacturers tailor their processes to accommodate unique requirements, such as specific material use or environmental tolerances.

- Support for Diverse Projects: From small-scale prototypes to full-scale production, manufacturers provide scalable solutions, often integrated with contract electronics manufacturing services for a more streamlined delivery.

Partnering with a specialized PCB assembly manufacturer gives businesses access to the tools, processes, and expertise needed to create high-quality boards that perform reliably in any application.

The PCB Assembly Process

A reputable printed circuit board assembly manufacturer follows a detailed process to deliver high-quality PCBs that meet client requirements. Every stage of the assembly process is handled with precision to maintain consistent results.

- Step 1: Component Placement

Manufacturers place components accurately using advanced surface-mount technology (SMT) or through-hole techniques. Automated machinery establishes efficiency and consistency, even in high-volume production. - Step 2: Soldering

Depending on the type of assembly, components are secured to the PCB using reflow or wave soldering. This process creates robust electrical connections that withstand rigorous use. - Step 3: Inspection and Testing

Quality checks, including Automated Optical Inspection (AOI) and functional testing, are conducted to identify defects or inconsistencies. Manufacturers also integrate specialized processes like prototype development services for small-scale runs before full production. - Step 4: Packaging and Logistics

Assembled boards are carefully packaged to preserve their integrity during transportation. Many manufacturers also provide value-added services like 3PL solutions to provide smooth delivery and integration into broader supply chains.

Each step in the process reflects the expertise and resources a professional manufacturer brings to the table, making sure every PCB meets strict quality standards and project goals.

Key Considerations for Choosing a Printed Circuit Board Assembly Manufacturer

Selecting the right printed circuit board assembly manufacturer is important when it comes to achieving high-quality, reliable PCBs that meet your production goals.

Here are 5 key factors to consider when making your choice:

- Experience with Diverse Applications: Look for a manufacturer with proven expertise in specific industries, such as medical devices or consumer electronics. This experience confirms that they understand the unique requirements of your products and can produce consistent quality.

- Advanced Quality Control Processes: A reliable manufacturer uses state-of-the-art tools, such as X-ray inspection and AOI, to verify the accuracy and functionality of every board. This helps minimize the risk of defects or delays.

- Scalable Production Capabilities: Whether you need prototypes, small batches, or full-scale production, the manufacturer should offer flexible options to meet your needs without compromising timelines or standards.

- Customization and Support Services: Manufacturers that provide value-added offerings, such as product engineering and design, can adapt their processes to align with your specific product goals.

- Reputation for Consistency and Reliability: Client reviews, case studies, and references offer insights into the manufacturer’s track record for delivering projects on time and within budget.

Choosing a PCB assembly manufacturer with the right expertise, technology, and scalability assures you receive high-performing PCBs tailored to your product and industry requirements.

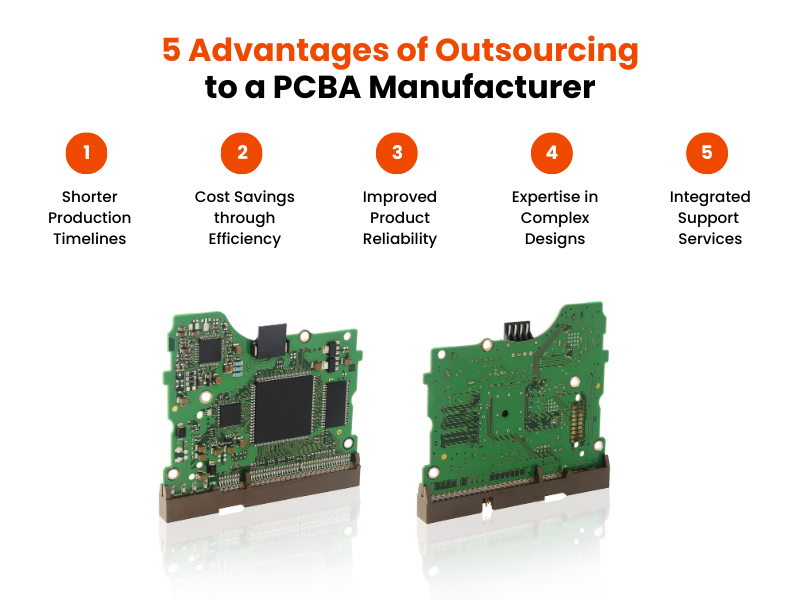

Advantages of Outsourcing to a Printed Circuit Board Assembly Manufacturer

Partnering with a specialized printed circuit board assembly manufacturer offers distinct advantages that streamline production and improve product outcomes including:

- Shorter Production Timelines: Manufacturers with advanced processes and equipment can handle complex assemblies faster, reducing lead times and helping you bring products to market quickly.

- Cost Savings through Efficiency: Efficient workflows and streamlined assembly processes lower production costs while maintaining high-quality standards. For businesses requiring aftermarket manufacturing, these cost efficiencies are critical for staying competitive.

- Improved Product Reliability: Rigorous testing and inspection at every stage of production minimize the likelihood of defects, delivering boards that meet stringent performance standards.

- Expertise in Complex Designs: Manufacturers experienced in handling intricate projects, such as printed circuit board assembly for multi-layer boards, bring the knowledge needed to manage advanced designs effectively.

- Integrated Support Services: Additional capabilities, such as contract manufacturing, help simplify supply chains by consolidating multiple services under one trusted partner.

These benefits make partnering with an experienced PCB assembly manufacturer an invaluable asset for businesses looking for reliable, cost-effective solutions tailored to their specific industry needs.

Industries That Rely on PCB Assembly Services

A specialized printed circuit board assembly manufacturer serves as a critical partner for industries that rely on precision and high-quality electronics. Their expertise addresses specific challenges across various sectors:

- Healthcare: PCB manufacturers support complex projects, such as diagnostic equipment and surgical devices, to meet the demands of manufacturing medical devices with strict regulatory compliance.

- Automotive: Reliable PCBs power important systems in modern vehicles, including safety electronics, infotainment systems, and electric vehicle powertrains.

- Consumer Electronics: From smartphones to smart home devices, PCB assembly manufacturers deliver durable and efficient boards that match the fast-paced demands of consumer markets.

- Industrial Equipment: Manufacturers provide robust PCBs for applications like power distribution equipment, 3D printers, and factory automation systems.

- Defense and Aerospace: These sectors depend on precise PCBs for mission-critical systems such as avionics, communication tools, and navigation systems.

Each industry depends on the specialized solutions provided by professional PCB assembly manufacturers, verifying the boards are designed to meet their unique application requirements.

Partner with a Printed Circuit Board Assembly Manufacturer You Can Trust

A printed circuit board assembly manufacturer is more than just a production partner; they are an important part of delivering reliable, high-performance electronics. By collaborating with an experienced contract manufacturer that offers these services, businesses benefit from streamlined production processes, cost savings, and superior product reliability.

MFG One provides custom solutions for clients in healthcare, automotive, consumer electronics, and more. With additional capabilities like product assembly services, we simplify the manufacturing process, helping you meet industry demands with confidence.

MFG One proudly serves clients in the United States, Canada, the United Kingdom, Mexico, and beyond, delivering customized PCBA solutions designed to meet their business goals.

Contact MFG One today for a free consultation!