Integrated Sourcing and Logistics

Industrial Manufacturing Services

At MFG One, we deliver industrial contract manufacturing services by combining in‑house assembly and testing with a network of global partners, giving you reliable sourcing, streamlined logistics, and strict quality control from start to finish.

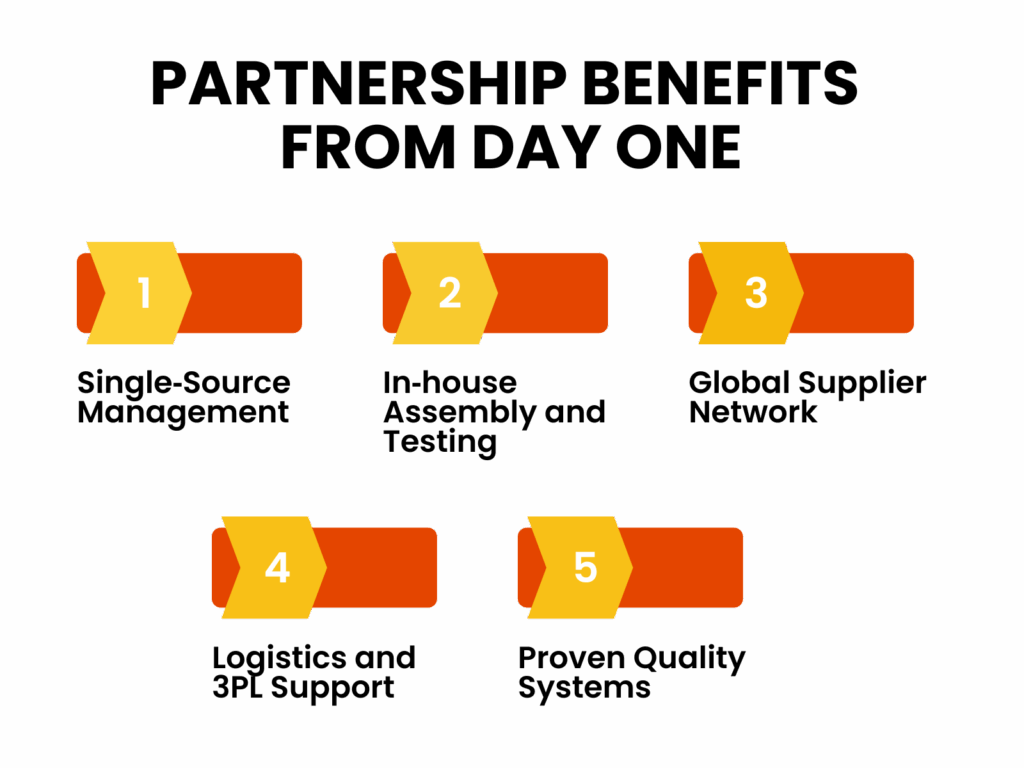

Partnership Benefits From Day One

Working with MFG One means gaining a partner who manages every stage of production with precision and accountability.

What you can expect:

One partner coordinating sourcing, assembly, and fulfillment

Every product validated against strict standards

Access to reliable partners for critical components

Warehousing, distribution, and returns handled seamlessly

ISO 13485 and FDA‑QSR compliance ingrained in our processes

Industrial Equipment We Build Daily

As a contract manufacturer in the USA, we combine in‑house expertise with managed global sourcing to deliver finished equipment ready for your production floor.

Turnkey Electronics Manufacturer

We oversee sourcing, assembly, testing, packaging, and delivery, partnering with vetted vendors for PCB manufacturing.

Embedded electronic modules

As part of our industrial manufacturing services, key parts are procured through vetted partners, then integrated, tested, and finalized in‑house.

Integrated control units

After sourcing critical boards and hardware, we complete wiring, enclosure integration, and final assembly in‑house for a fully tested product.

Control panels for industrial machinery

Outsourced components are built, wired, and tested in‑house to meet demanding performance standards.

Custom sensor modules

We manage suppliers for specialized components, then assemble and validate them in‑house for accuracy and reliability.

Industrial monitoring devices

Through our industrial manufacturing services, critical parts are sourced, then assembled, tested, and quality‑checked in-house before delivery.

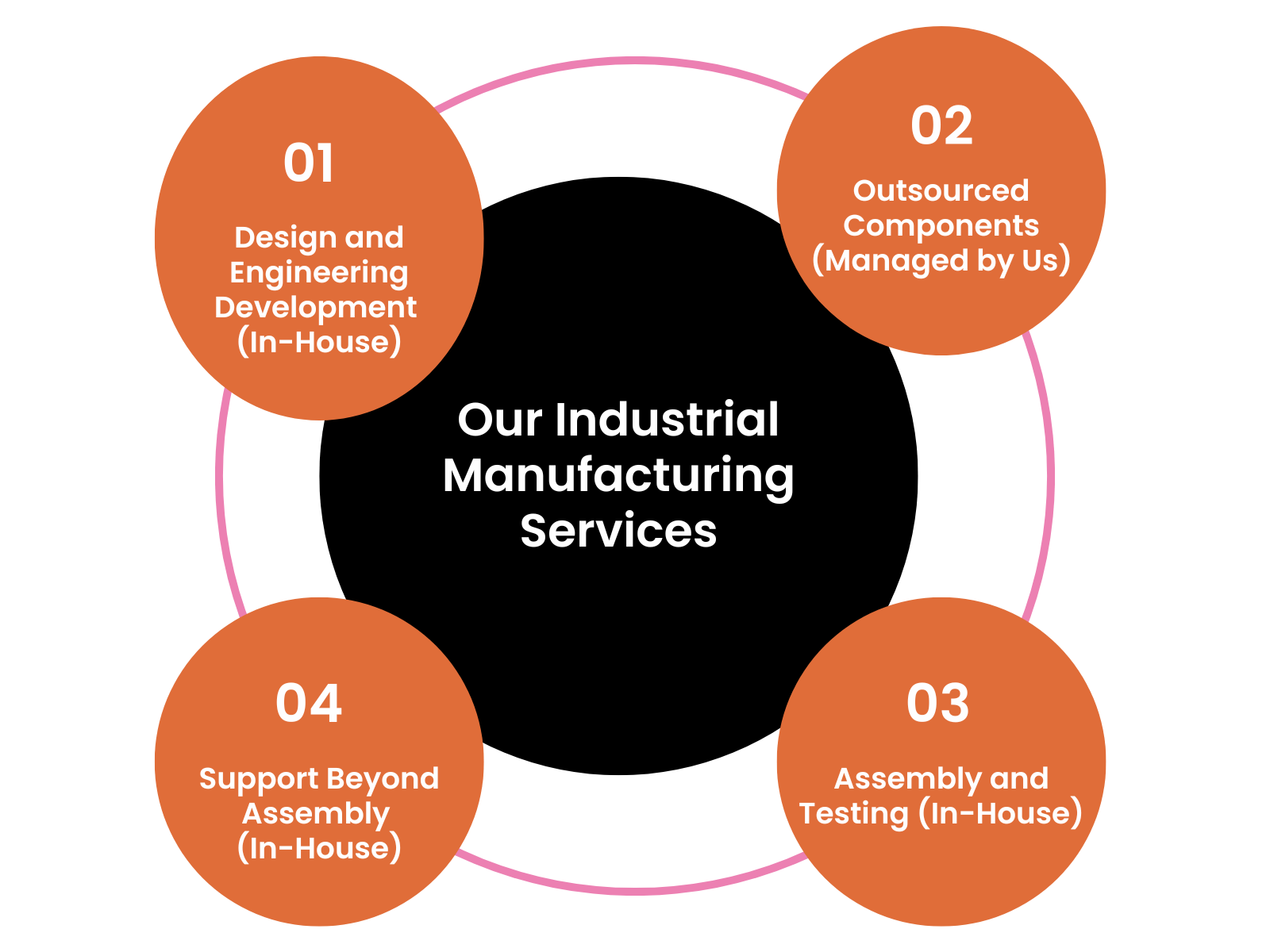

Our Industrial Manufacturing Services

Our industrial manufacturing services combine in‑house capabilities with carefully managed vendor relationships. You get one partner to oversee every stage with streamlined communication, material sourcing, and logistics coordination.

(In-House)

As an electronic contract manufacturer, we carry out all core operations within our own facility, giving us full control over quality, lead times, and production flow. This in-house approach allows for tighter oversight, faster turnaround, and greater consistency across every build.

While we don’t manufacture parts internally, we manage a global network of vetted partners for specialized production and materials. Our team handles all communication, quality expectations, and timelines, so you don’t have to coordinate with multiple vendors.

→PCB manufacturing

→Plastic injection molding

→Mold tooling

→Metal fabrication

Our Quality and Certifications

Quality drives everything we do, whether we’re providing industrial manufacturing services or building for medical or commercial markets. Every product is assembled, tested, and validated in-house to meet strict requirements before it leaves our facility.

While some certifications apply specifically to medical devices, they reflect the level of quality and process control we bring to every build, industrial included.

Certifications and standards we follow:

ISO 13485 FDA QSR-compliant :2016 certified:

ISO 13485-certified and FDA QSR-compliant support for prototypes, validated assemblies, and full production builds.

FDA‑QSR registered facility:

Aligned with federal regulatory requirements

cGMP and Lean Manufacturing principles:

Applied to ensure efficiency, traceability, and consistency

Regulatory support:

Guidance with NRTL certifications, RoHS compliance, and FDA submissions

Industries We Serve

As an industrial manufacturing service provider, we support manufacturers across a wide range of regulated and technical industries. Our in-house capabilities, trusted vendor network, and strict quality protocols allow us to meet the demands of complex products for a variety of applications.

We adapt to your product requirements while maintaining full accountability through every stage. Industries we support include:

ISO 13485-certified and FDA QSR-compliant support for prototypes, validated assemblies, and full production builds

Assembly of control boards, monitoring devices, and interface modules with ruggedized performance

Box-build assemblies and multi-component integration for scalable product lines

Sourced and assembled components for sensors, control units, and connected systems

OEM solutions built for efficiency, with sourcing, production, and logistics managed through a single partner

Get In Touch

Experience the Difference With a Partner Like MFG One

Partner with MFG One, a US‑based industrial contract manufacturer serving the United States, Canada, Mexico, the United Kingdom, and beyond. As your single‑source provider, we combine in‑house assembly and testing with a managed network of global suppliers, giving you consistent quality, scalable production, and streamlined communication from day one.

Work with a partner who handles every stage with precision and accountability. Connect with MFG One today and discover how we can help bring your next build to life.